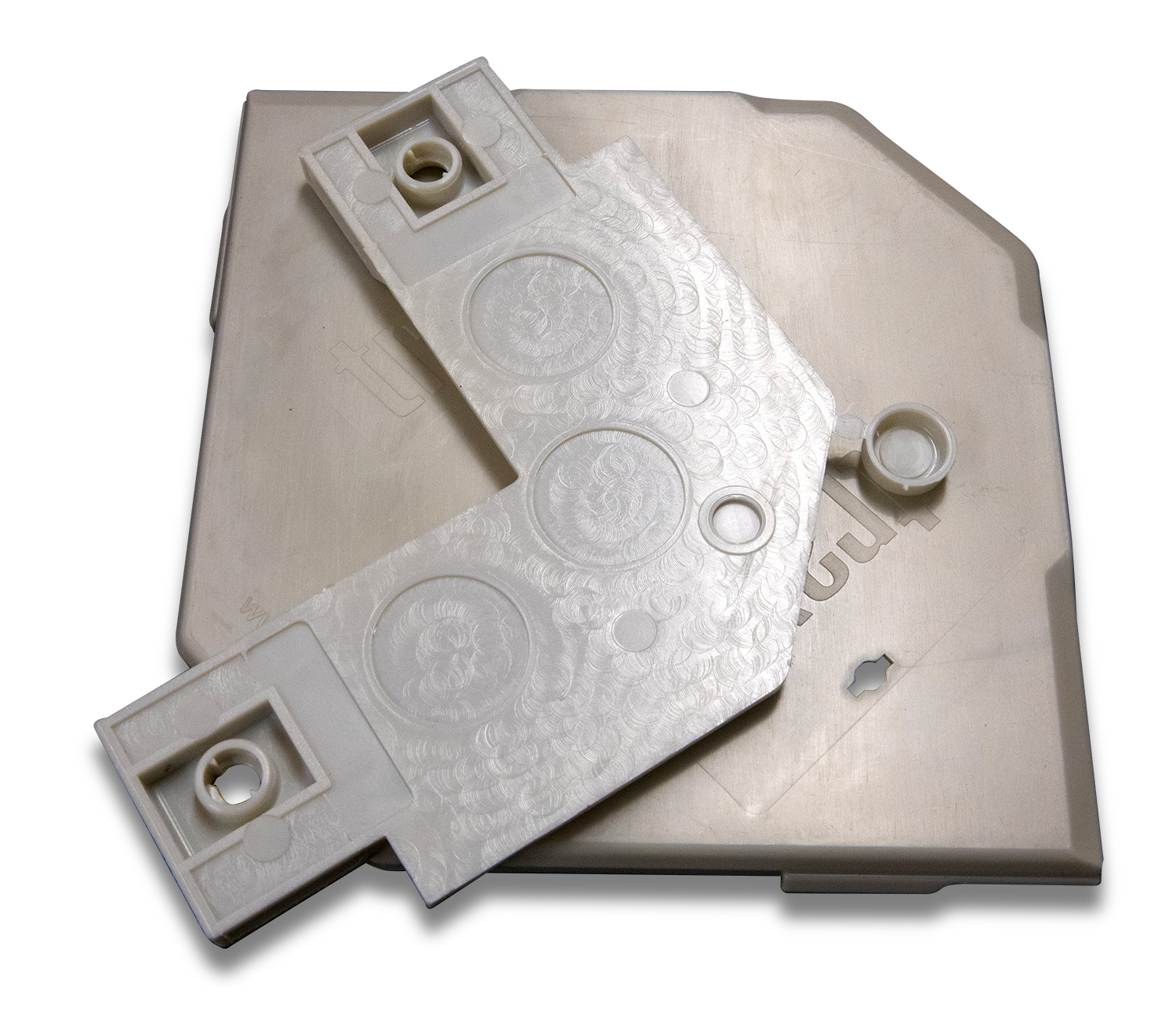

Rapid Prototyping Services: Bridging Design and Efficient Production

In today’s fast-paced manufacturing world, the ability to quickly turn ideas into tangible products is crucial. Rapid prototyping services stand at the forefront of this revolution, offering a bridge between innovative design and efficient production. This blog will explore how rapid prototyping enhances production efficiency, answering the critical question for many manufacturers and designers. Understanding […]