Injection Moulding for the Construction Industry: What You Need to Know

27 June 2025

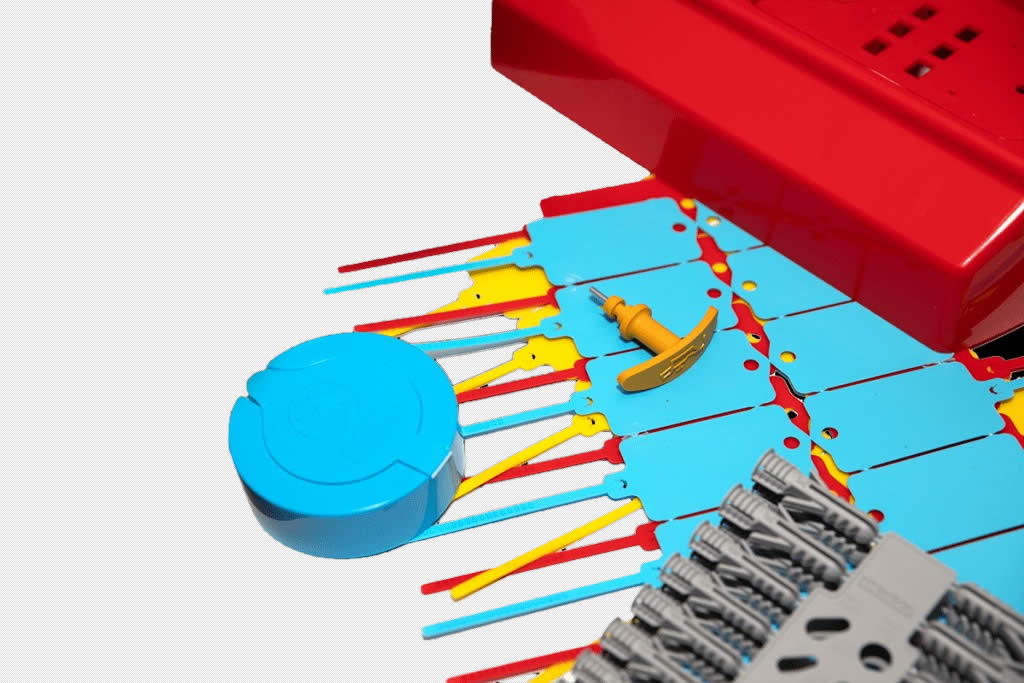

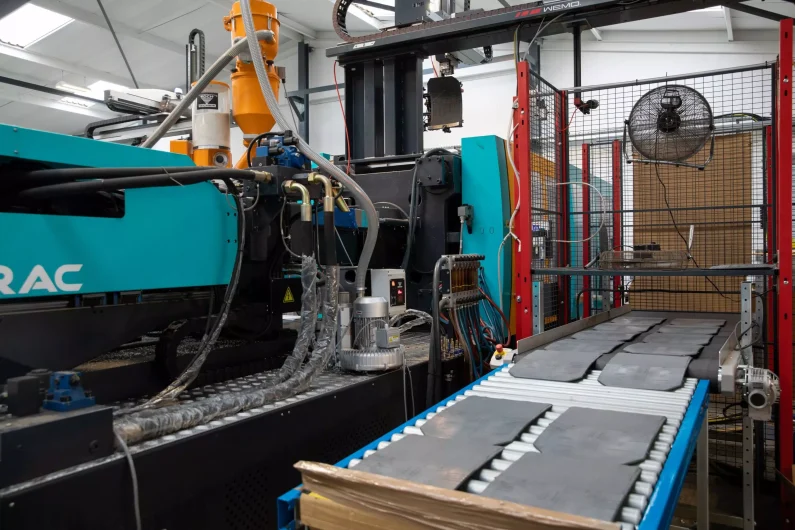

Stephens Plastics: Supplying Durable Moulded Components for the UK Construction Sector From facades to formwork, today’s construction projects increasingly rely on construction injection moulding to deliver long-lasting, weather-resistant components. At Stephens Plastics, we have built strong partnerships with architects, contractors, and OEM suppliers by manufacturing plastic parts engineered for the harshest environments. In this comprehensive […]