Achieving Timeliness without Compromising Quality: The Stephens Plastics Approach to Plastic Injection Moulding Turnaround Times

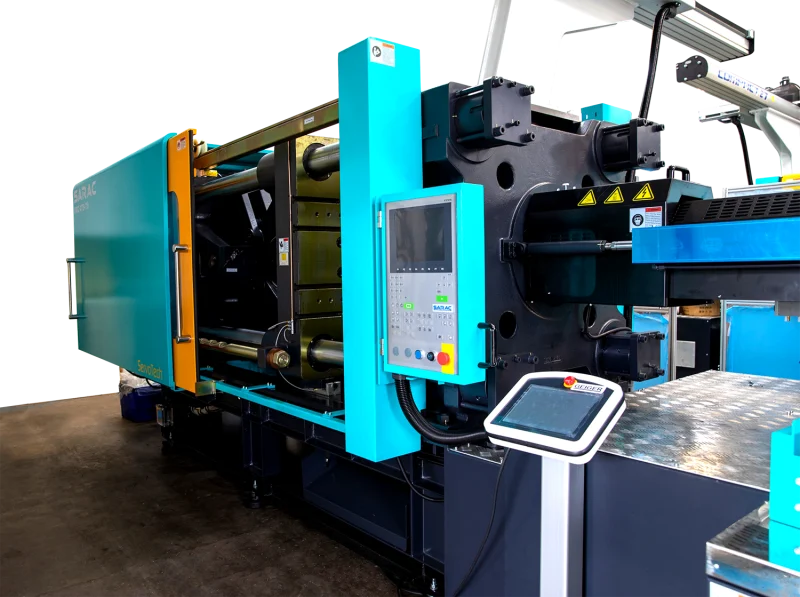

In the world of manufacturing, time is of the essence. With market dynamics rapidly changing, businesses need partners who can deliver high-quality products on time, every time. At Stephens Plastics, we understand this well. Our commitment to timely delivery, without compromising on quality, is part of our ethos. But what does this mean in the […]