Metal casting is a type of metalworking process that uses liquid metal and a mould. It has been around for thousands of years and was in fact one of the earliest methods for making swords. Today, metal casting is relied upon across a wide range of industries. Used to make wind turbines through to pillar drills.

Some other products made using the process include:

- Engine blocks

- Plumbing parts

- Metal statues

- Gearbox housings

- Crankshafts

The metal moulding process remains one of the most valuable and versatile methods for manufacturing high quality metal tools and components.

Metal Casting Summarised

Put simply, metal casting is a metal fabrication technique that involves pouring molten liquid metal into a specially designed mould.

The inside of the mould will be designed with a negative impression of the desired component. As a result, once the molten metal has cooled and solidified in the mould, it will take a shape of the final part and reflect the details that the mould has. After it has cooled, the component can be removed from the mould and undergo any further finishing processes.

There are different variations of metal casting, all of which have their own specific advantages. The type of metal casting greatly depends on the type of component being made, and the type of metal that it is going to be made from.

The metal casting process is a highly versatile process that can be used across many different sectors, however there can be certain design considerations that must be taken into account – such as the shrinkage of metal when it is cooling. With this in mind, if you are looking to use metal casting as a manufacturing process, it is important you work with a metal casting company that is highly equipped and experienced with the knowledge and facilities needed to get the job done properly.

Some advantages include:

- Can be used for mass production of metal parts

- Also suitable for large one-piece parts

- Can produce thick heavy-duty components with ease

- Offers great material versatility

Metal Casting Stages

The metal casting process has a few stages – which will sometimes vary depending on the type of casting – in order to successfully create a metal component. They are as follows:

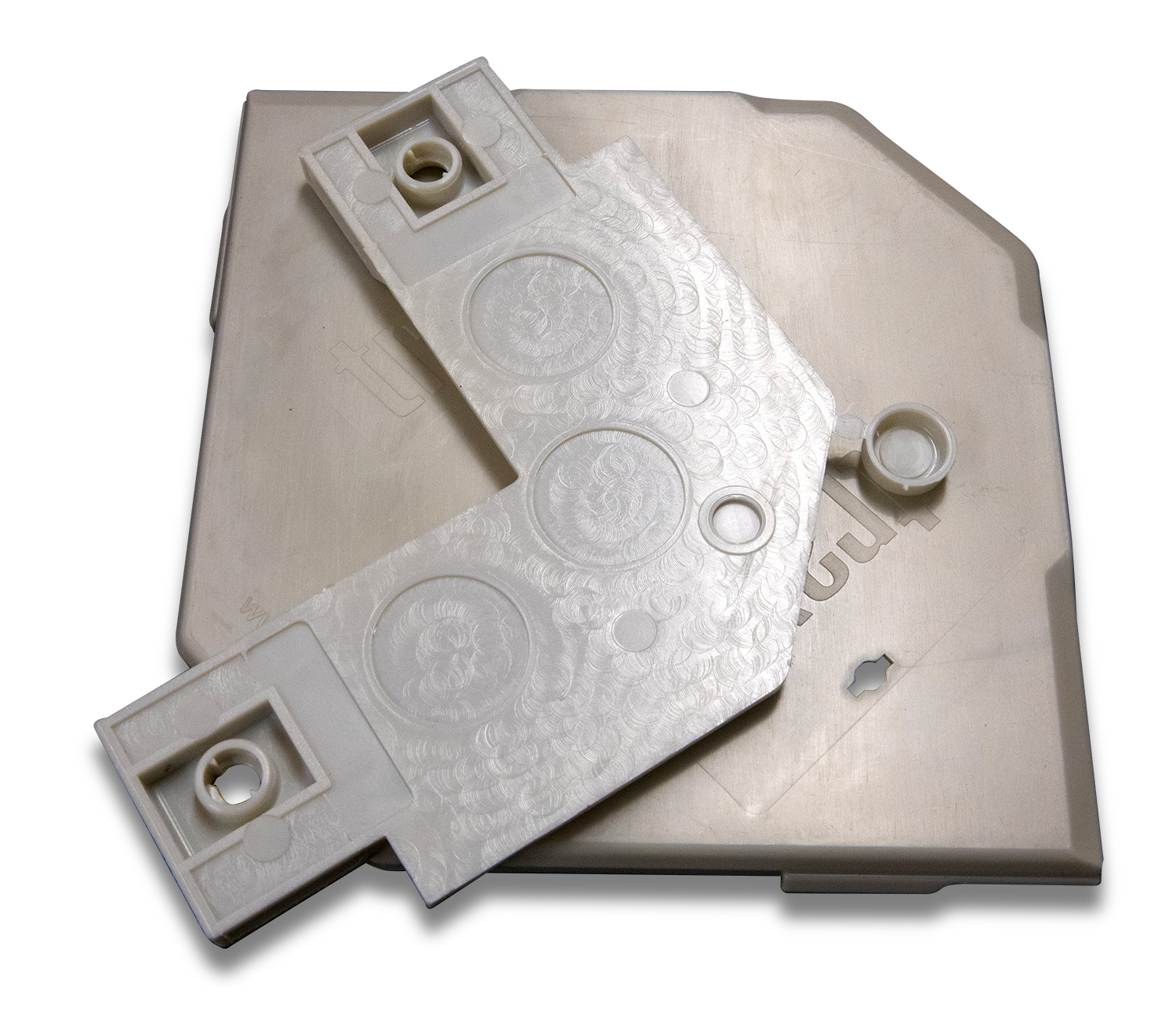

Pattern making: Lots of metal casting applications will require the fabrication of a pattern – this is a duplicate of the desired component that will be cast. Patterns can be made from all sorts of materials, including wax, wood, and plastic.

Designing the core: For hollow parts, a core will need to be designed. This is usually in the form of a solid piece of metal which will be placed inside the mould cavity.

Making the mould: Depending on the type of shape needed, there can be many ways in which to make a metal casting mould, however permanent moulds are usually made using CNC machining.

Filling it: Once the mould is ready, the metal is heated up until it melts into a molten liquid. It is then poured into the mould (different pressures are used depending on the casting type) until the shape of the mould is filled before being left to cool.

Removing the part: Once cooled, the metal casted part is removed from the mould. Some processes such as sand casting require the mould to be destroyed in order to get to the actual component, whereas permanent moulds are simply pulled apart into two halves so that they can be used over and over again.

Metal Mouldings UK

If you are looking for a metal casting company, then look no further than Stephens Plastic Mouldings Mouldings. With all of the experience and knowledge you would expect from metal casting moulders in the UK, we can support you with a wide range of requirements and applications.

Explore our website for more information. Alternatively call 0121 544 5808 to speak to a member of our helpful and friendly team.

Found this blog helpful? Then you may wish to read our previous blogs on: What Is Vacuum Forming? or What Makes Plastic Injection Moulding So Popular?