Innovative Overmoulding Solutions: Enhancing Product Durability

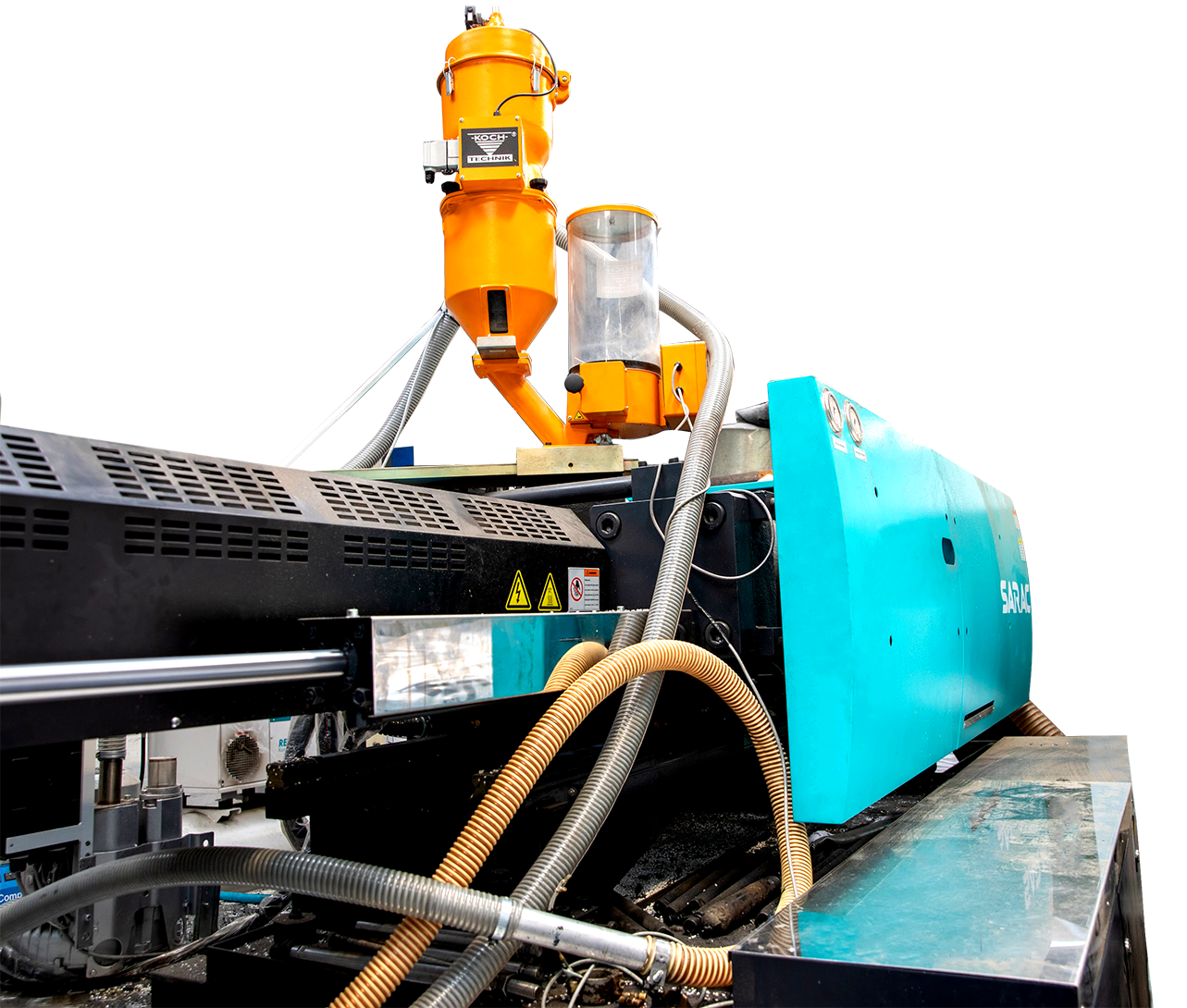

Discover innovative overmoulding solutions. Overmoulding, a key innovation in manufacturing, enhances the durability and functionality of products. This blog delves into these advanced techniques, answering the crucial question: How does overmoulding improve product durability? Understanding Overmoulding Overmoulding involves adding an additional layer of material over an existing part, often combining different types of plastics or […]