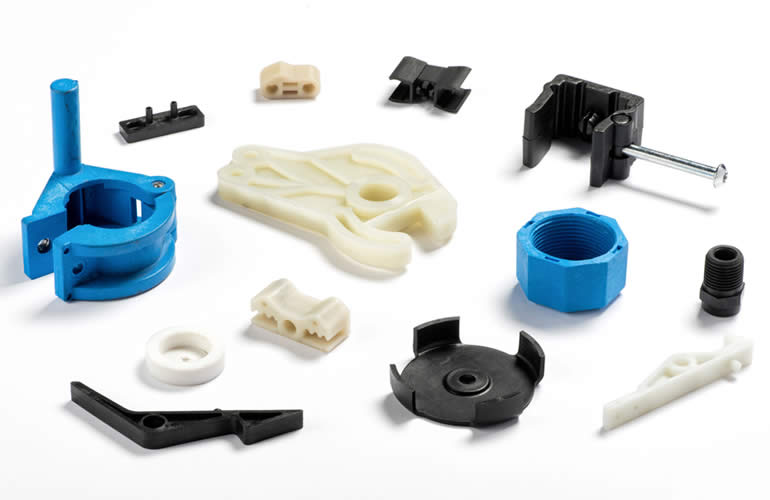

Automotive, Medical and Sustainable Plastic Injection Moulding

5 February 2026

Manufacturing at the Intersection of Performance, Precision and Sustainability Modern manufacturing demands more than volume production. It requires sector-specific expertise, regulatory awareness, material engineering capability and sustainable production systems. At Stephens Plastic Mouldings, we support automotive manufacturers, medical device companies and sustainability-focused organisations with precision plastic injection moulding solutions engineered for performance and long-term reliability. […]