Manufacturing Plastic Components with Injection Moulding

16 February 2026

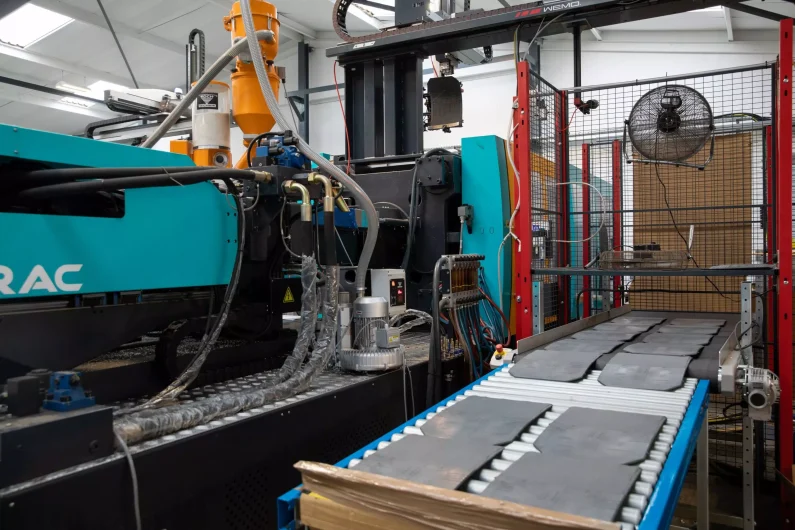

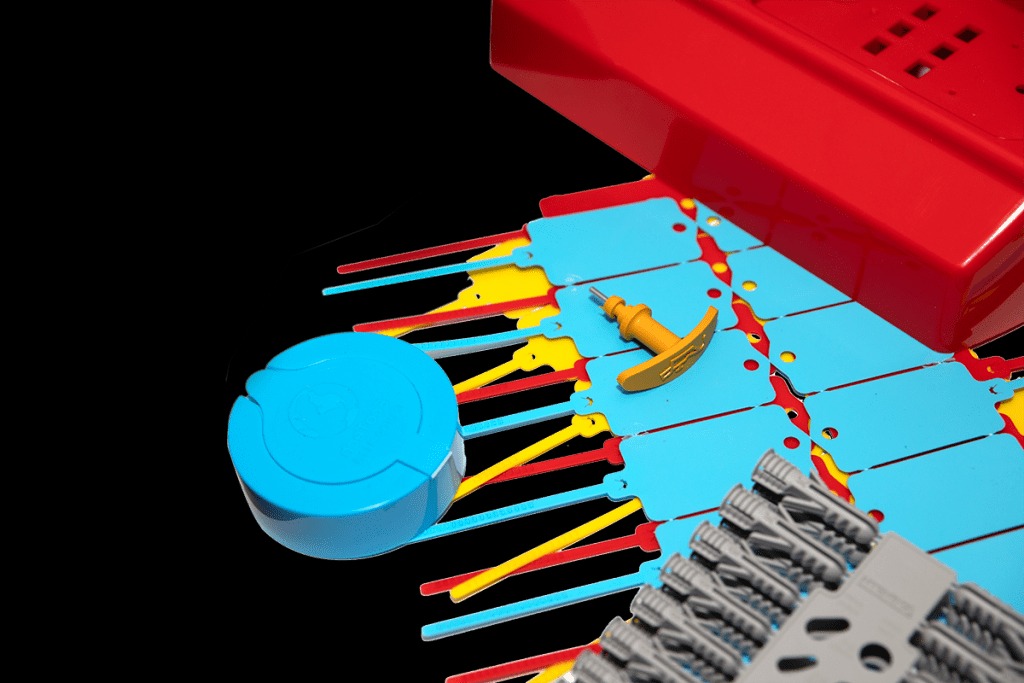

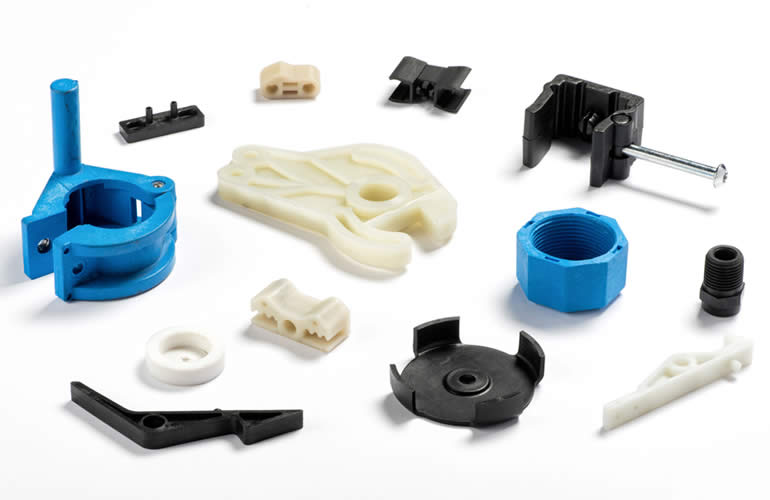

Why Plastic Injection Moulding Is the Most Efficient Choice for Your Business Efficiency in manufacturing means maximising productivity while minimising time, material waste and cost. Why Plastic Injection Moulding Drives Manufacturing Efficiency Plastic injection moulding remains one of the most efficient methods for manufacturing plastic components at scale. At Stephens Plastic Mouldings, we use […]