A Guide for Engineers, Buyers & OEMs

Choosing a plastic injection moulding company isn’t just about finding someone who can shape plastic. It’s about securing a strategic partner who offers technical expertise, quality control, advanced infrastructure, and unwavering reliability across every production run.

At Stephens Plastic Mouldings, we help customers across the UK – from Birmingham to Bristol, Cardiff to Cambridge – bring their plastic products to life with confidence, speed, and engineering precision.

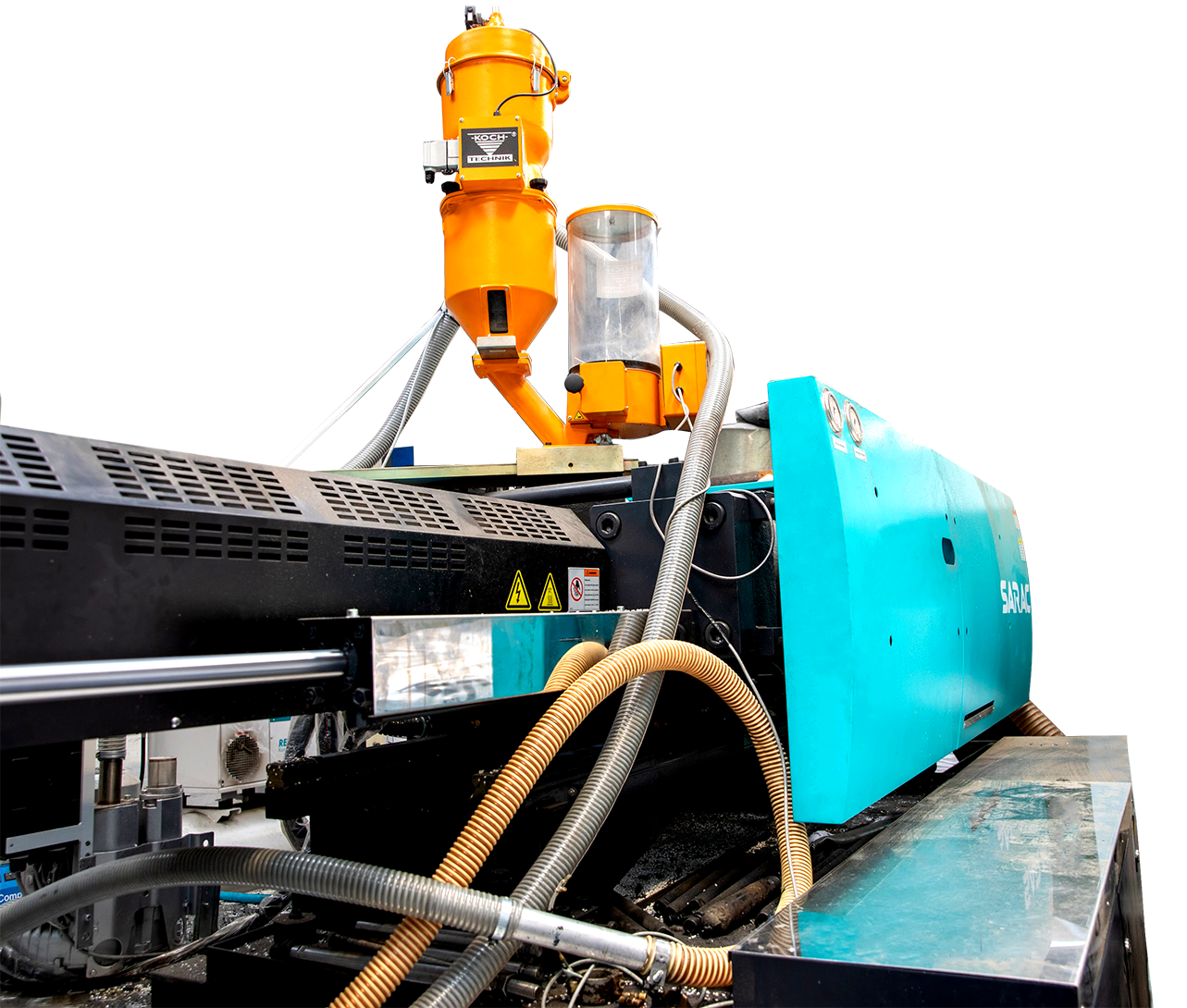

Why Facilities and Ancillary Equipment Matter

A good injection moulding company invests in more than machines – it invests in performance infrastructure.

Our production floor features a fleet of high-precision injection moulding machines (25T to 470T), but what makes our results exceptional is the ancillary equipment that supports the process:

1. Hopper Loaders

Automatically feed materials into the machine to ensure uninterrupted cycles.

2. Granulators

Reprocess runners and reject parts for cost-effective, sustainable moulding.

3. Temperature Controllers

Maintain thermal stability across machine circuits, ensuring perfect parts every time.

These ancillaries are not secondary – they are mission-critical to maintaining cycle time efficiency, part consistency, and material integrity.

UK-Based, ISO-Certified & Scalable

1. Stephens Plastic Mouldings is:

- Proudly UK-based and strategically located in the West Midlands.

- ISO 9001:2015 certified.

- Fully equipped for prototype, low-volume, and full-scale production.

2. We specialise in end-to-end services, including:

- Design for Manufacture (DFM).

- Tooling (in-house or managed).

- Precision moulding.

- Secondary operations (e.g., drilling, welding, assembly).

- Bespoke packaging and delivery.

No matter your sector – automotive, electronics, construction, or medical – our engineers ensure accuracy, hygiene, and cost-efficiency with every order.

What to Expect From Stephens Plastic Mouldings

| Core Strength | What It Means for You |

|---|---|

| Free trial tools | Reduce tooling risk before full production |

| Responsive UK team | Quick quoting and project support |

| Competitive pricing | Optimised processes and minimal waste |

| Quality-controlled output | Batch traceability and in-line inspection |

| End-to-end project support | One partner from concept to final product |

Our ancillary systems and experienced team give us the control to meet demanding tolerances while keeping prices competitive and lead times tight.

FAQs for Electronics Buyers

1. What should I look for in a plastic injection moulding company?

Look for ISO certification, UK-based support, in-house tooling, quality ancillary equipment, and material traceability. Stephens Plastic checks every box.

2. Do you offer moulding services for low volume or prototyping?

Yes, we provide low-volume production runs and free trial tooling on select projects — ideal for startups or market testing.

3. Can you mould complex parts with tight tolerances?

Absolutely. Our machines and temperature-controlled systems ensure high repeatability and precision, even on geometrically complex parts.

4. What industries do you serve?

We support sectors including automotive, electronics, construction, packaging, and medical – with tailored materials and QA standards.

5. How fast can Stephens Plastic deliver moulded parts?

We aim for delivery within 2-6 weeks from tooling sign-off, depending on complexity. Our UK-based operation allows us to avoid overseas delays.

Ready to Work With a Reliable UK Plastic Moulding Partner?

We combine modern machinery, experienced staff, and robust process control to deliver your plastic parts with confidence. Whether you’re a product developer, buyer, or engineer – Stephens Plastic Mouldings is here to support your goals.

To request a quote or book a free consultation

Contact Stephens Plastics Today

Email: sales@stephensplasticmouldings.co.uk

Phone: 0121 544 5808