Why Choosing the Right Manufacturer Determines Project Success

Selecting a plastic parts manufacturer is not a procurement exercise. It is a strategic decision that directly affects product quality, delivery reliability, total cost of ownership and long-term scalability.

At Stephens Plastic Mouldings, we work with customers who have experienced the consequences of choosing the wrong partner: missed deadlines, inconsistent quality, tooling issues and unexpected costs. Equally, we see the measurable benefits when manufacturing decisions are made with engineering insight, process control and partnership in mind.

This guide explains how to evaluate plastic parts manufacturers in 2026—what matters, what doesn’t, and how to identify a partner that will support your product beyond the first production run.

Proximity Matters—But Control Matters More

Why UK-Based Manufacturing Still Delivers a Competitive Advantage

Proximity is not just about geography. It is about access, accountability and speed of decision-making.

Working with a UK-based plastic parts manufacturer offers:

- Faster communication and issue resolution

- Easier site visits and technical collaboration

- Shorter lead times and reduced logistics risk

- Better control over quality and process changes

For regulated, time-sensitive or evolving products, local manufacturing significantly reduces risk across the project lifecycle.

Manufacturing Capability vs Manufacturing Discipline

Why Equipment Alone Is Not Enough

Many manufacturers can mould parts. Far fewer can do so consistently, repeatedly and at scale.

When evaluating a plastic parts manufacturer, capability must be matched with discipline:

- Documented, repeatable processes

- Stable tooling strategies

- Controlled production parameters

- Embedded quality systems

At Stephens Plastic Mouldings, manufacturing discipline is built around ISO 9001 quality management, ensuring consistency from prototype through to full production.

Engineering Involvement Is a Leading Indicator of Success

Design for Manufacture (DFM) Is Non-Negotiable

The most reliable plastic parts manufacturers are involved before tooling is cut, not after problems appear.

Early engineering involvement enables:

- Reduced tooling revisions

- Optimised wall thickness and geometry

- Better material selection

- Lower scrap and rework rates

- Improved cycle efficiency

Manufacturers who offer DFM support protect your budget, timeline and product integrity from the outset.

Tooling Strategy: Short-Term Cost vs Long-Term ROI

Why Tooling Decisions Define Future Flexibility

Tooling is one of the largest investments in plastic parts manufacturing. Choosing a manufacturer who treats tooling as a performance asset—not a cost to minimise—protects long-term ROI.

A strong tooling strategy considers:

- Expected volumes and scalability

- Tool life and maintenance

- Cooling efficiency and cycle time

- Tolerance control and repeatability

The right partner aligns tooling decisions with your product roadmap, not just the first order quantity.

Quality Systems: Certification Is the Starting Point, Not the Finish Line

What ISO 9001 Really Signals

ISO 9001 certification indicates that a manufacturer operates under structured quality systems. But the real value lies in how those systems are applied.

At Stephens Plastic Mouldings, quality is:

- Embedded into tooling and process design

- Monitored throughout production

- Documented for traceability and accountability

- Continuously improved through data and feedback

This approach reduces risk, not just paperwork.

Sustainability and Responsibility as Commercial Factors

Sustainability is no longer a branding exercise. It is a commercial and operational requirement.

Leading plastic parts manufacturers now integrate:

- Waste reduction through efficient design

- Energy-efficient processing

- Durable components with longer service life

- Responsible material selection

When done correctly, sustainable manufacturing improves cost stability, compliance and supply resilience.

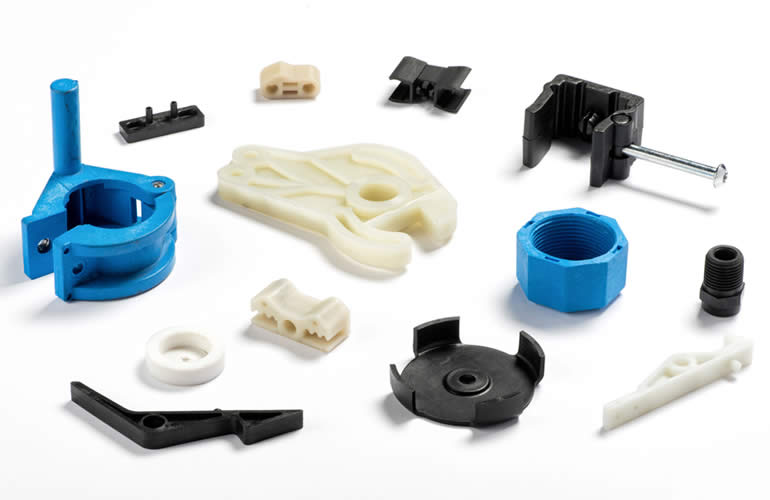

What Sets Stephens Plastic Mouldings Apart

Customers choose Stephens Plastic Mouldings because we provide:

- UK-based plastic injection moulding

- ISO 9001 certified quality systems

- Engineering-led DFM and material selection

- Precision tooling and controlled production

- Low-volume through to scalable manufacturing

- Transparent communication and long-term partnership

We are not just a supplier. We are a manufacturing partner invested in outcomes.

FAQs

1. How do I choose the right plastic parts manufacturer in the UK?

Look for UK-based production, ISO 9001 certification, engineering support, proven tooling expertise and the ability to scale from prototype to production.

2. Why is ISO 9001 important when selecting a plastic manufacturer?

ISO 9001 ensures consistent quality management, traceability and continuous improvement—reducing production risk and variability.

3. Should a plastic parts manufacturer offer design for manufacture support?

Yes. DFM support is critical to reducing tooling costs, preventing defects and ensuring parts are optimised for production from day one.

4. Is UK plastic injection moulding more reliable than overseas suppliers?

For many projects, yes. UK manufacturing offers better communication, faster lead times, stronger quality control and lower supply chain risk.

5. Can Stephens Plastic Mouldings support long-term production partnerships?

Absolutely. We specialise in long-term manufacturing partnerships, supporting products from early development through scalable, repeatable production.

Final Insight: The Right Manufacturer Reduces Risk Before It Appears

Choosing a plastic parts manufacturer is about future certainty, not just current pricing.

The right partner:

- Anticipates issues before they occur

- Protects quality at scale

- Aligns manufacturing decisions with commercial goals

- Supports growth, change and optimisation over time

At Stephens Plastic Mouldings, our role is to make manufacturing predictable, scalable and commercially sound.

Call to Action

If you’re evaluating plastic parts manufacturers and want a UK-based partner that delivers engineering expertise, ISO-certified quality and long-term production confidence, our team is ready to help.

Contact Stephens Plastic Mouldings to discuss your project or request a tailored quotation.