Why Plastic Injection Moulding is the Smarter Alternative in 2025

Metal casting has long been a reliable manufacturing process, particularly for producing robust components. But in today’s fast-paced manufacturing landscape – where efficiency, cost reduction, and design flexibility are non-negotiable – plastic injection moulding has emerged as a smarter, more agile solution. At Stephens Plastic Mouldings, we help forward-thinking manufacturers in automotive, construction, medical, and consumer sectors make that transition.

Why Businesses Are Replacing Metal Casting with Plastics

Many of our clients originally relied on metal casting for its strength and legacy applications. However, once they’ve trialled plastic injection moulding, they’re often surprised by the improvements in performance, lead time, and total cost of ownership. Here’s why more UK manufacturers are making the switch.

Benefits of Plastic Injection Moulding vs Metal Casting

1. Faster Turnaround, Lower Costs

Plastic injection moulding dramatically reduces production cycle times. Unlike metal casting – which involves long cooling periods and intensive post-processing – plastic components are moulded and ejected in seconds, ready for use or minimal finishing. This efficiency reduces tooling wear, labour time, and overall cost per unit.

2. Design Flexibility

Complex geometries, undercuts, overmoulding, living hinges—these are all difficult or impossible with metal casting. Injection moulding enables the production of lightweight, integrated parts that reduce assembly steps, improve aesthetics, and deliver higher functional value in a single shot.

3. Weight Reduction Without Performance Loss

High-performance polymers like acetal, nylon, polycarbonate, and PBT offer strength-to-weight ratios that often match or exceed cast metal alloys. For example, in automotive and aerospace, this translates directly to fuel savings and reduced carbon emissions.

4. Sustainability Advantages

Plastic injection moulding is highly material-efficient, with minimal waste. Many of our clients opt for recycled polymers or regrind material, reducing both environmental impact and material cost. In contrast, metal casting generates slag, requires energy-intensive melting, and often uses virgin metals.

5. Tooling & Scalability

Injection moulding tools may have higher upfront costs – but they last longer and scale more efficiently. Once your part is validated, we can produce hundreds of thousands of units with consistent quality and traceability.

Real-World Application: Supporting UK Manufacturers

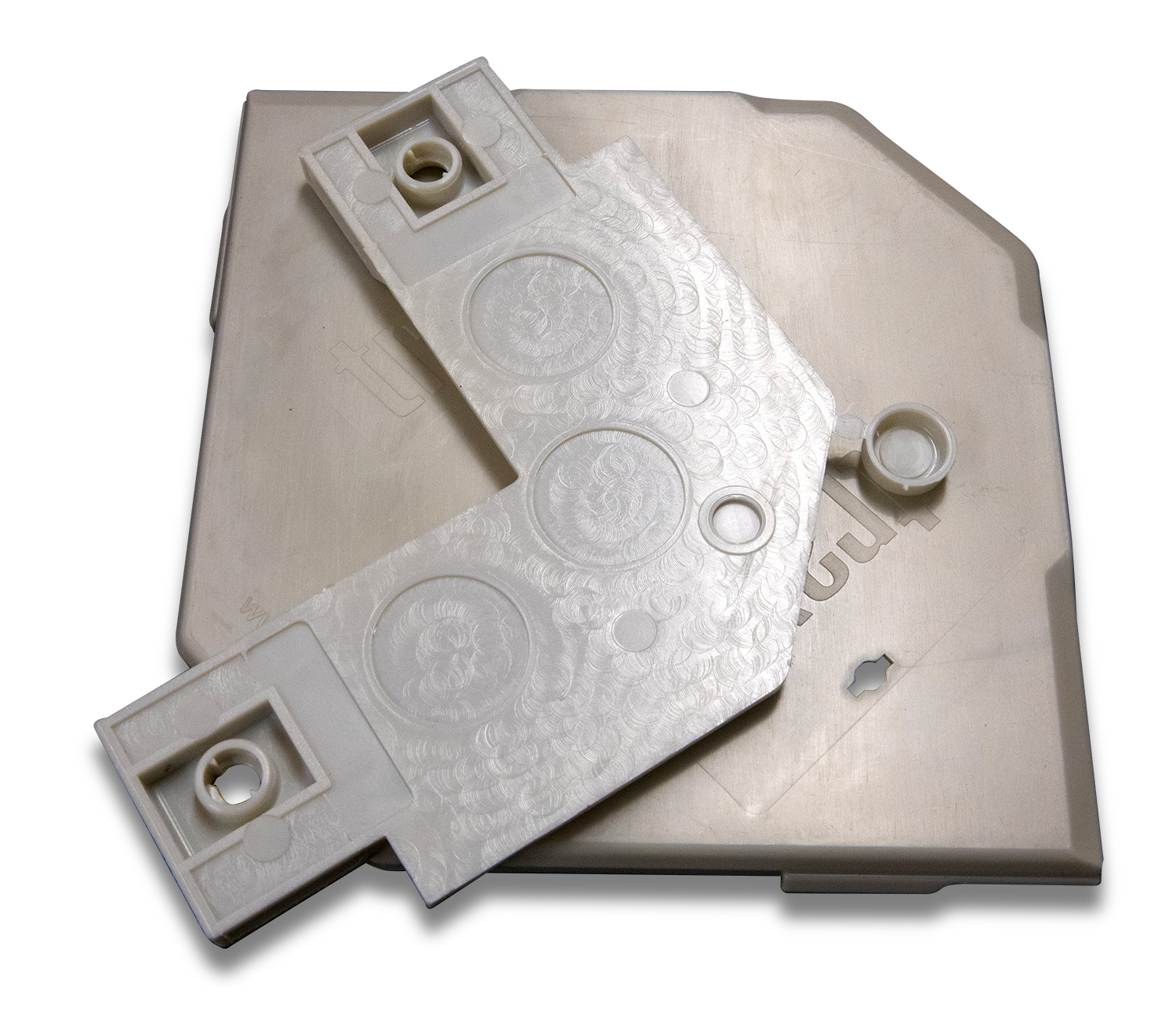

We’ve helped clients across the Midlands and beyond replace metal housings, brackets, and mechanical interfaces with precision-moulded plastic parts.

The outcome?

Lower costs, faster lead times, and improved ergonomics – especially in sectors where weight, compliance, and chemical resistance are critical.

FAQs

1. Is plastic injection moulding really strong enough to replace cast metal?

Yes. Modern engineering plastics can rival or exceed the strength of many cast metals while offering better corrosion resistance and lighter weight.

2. How much cheaper is plastic injection moulding than metal casting?

On average, plastic moulded parts cost 30-70% less per unit due to reduced material costs, faster cycles, and lower energy use.

3. Can Stephens Plastic help redesign my metal part for injection moulding?

Absolutely. Our team offers design for manufacture (DFM) support and prototyping services to re-engineer your part for plastic without compromising performance.

4. Do you offer sustainable alternatives to metal casting?

Yes. We use recyclable and regrind thermoplastics, helping clients meet sustainability targets while reducing weight and cost.

5. What industries are making the switch from metal to plastic?

Automotive, electronics, medical, and industrial equipment manufacturers are leading the shift – benefiting from injection moulding’s speed, scalability, and precision.

Ready to Replace Cast Metal with High-Performance Plastics?

Stephens Plastic Mouldings has the experience, tooling, and materials expertise to help you transition from traditional metal casting to future-ready plastic injection moulding.

Whether you’re based in Birmingham or beyond, we’re here to reduce your costs and increase your component performance.

Get in touch with our team today

Email: sales@stephensplasticmouldings.co.uk

Phone: 0121 544 5808