Stephens Plastics: Your UK Experts in High-Volume Injection Moulding

At Stephens Plastics, we’ve built a reputation as the go-to experts for plastic injection moulding in the UK. For businesses that require consistency, reliability, and efficiency in mass production, high-volume injection moulding remains the unrivalled solution.

In this blog, we will break down why injection moulding is the top choice for scalable production, how it meets the demands of various industries, and why Stephens Plastics is your trusted partner for achieving production goals.

What Is High-Volume Injection Moulding?

High-volume injection moulding is the process of producing thousands to millions of plastic parts using a precision-engineered mould. This method offers repeatability and cost-efficiency, especially when producing parts in bulk.

It’s particularly effective for:

- Automotive components.

- Medical device parts.

- Consumer electronics.

- Packaging.

- Industrial components.

Each cycle can produce complex parts with tight tolerances and consistent quality, all while reducing waste and lowering per-unit costs.

Why Is Injection Moulding Best for Scalable Production?

1. Speed and Efficiency

Once the initial tooling is created, the moulding process is extremely fast. Machines can produce multiple units per minute, which is ideal for large-scale production runs.

2. Low Cost Per Part

While tooling requires an upfront investment, the cost per unit drops significantly as volumes increase. This makes high-volume injection moulding the most economical option for mass production.

3. Minimal Waste

The injection moulding process uses only as much material as required, with little excess. Most systems can also recycle scrap material back into the production cycle.

The Benefits for Different Industries

Automotive

In the automotive sector, where durability and precision are vital, injection moulding enables production of dashboard components, clips, fasteners, and more – all in high volumes.

Healthcare

For medical devices and disposables, consistency is critical. Injection moulding ensures each part meets regulatory requirements and patient safety standards.

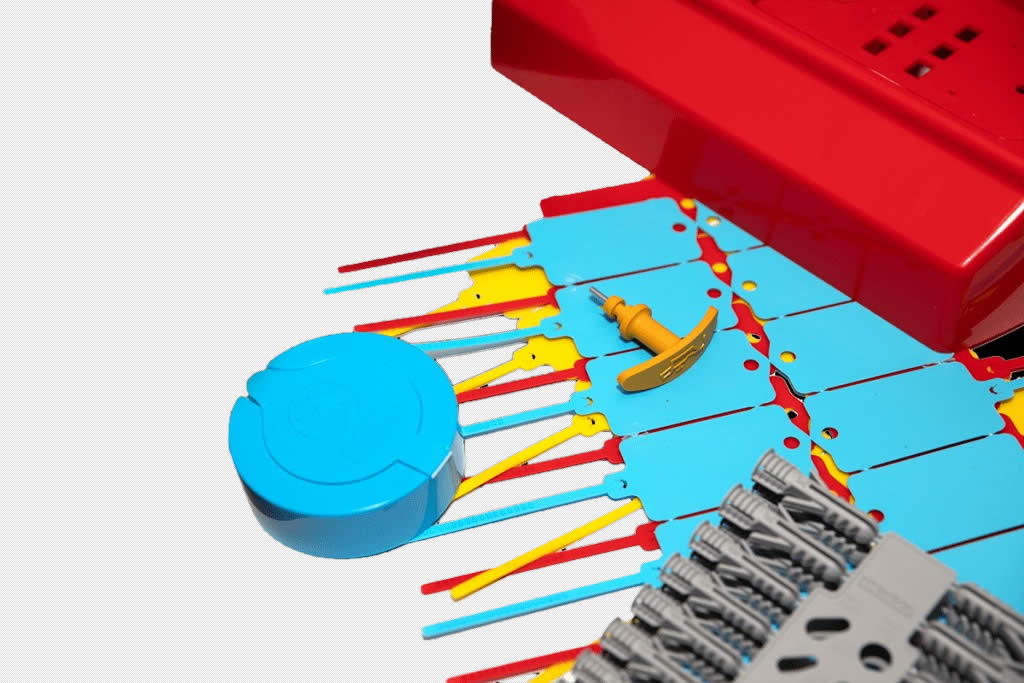

Consumer Goods

Injection moulding is behind many everyday items – from packaging to toys. Its ability to scale while maintaining quality is why it’s preferred across the consumer product landscape.

Industrial Equipment

Even in heavy industries, plastic components play a critical role. High-volume injection moulding supports the need for resilience and uniformity in tough environments.

Is Injection Moulding Cost-Effective for Startups?

Absolutely. While high-volume injection moulding has traditionally served large enterprises, many startups now benefit from scalable tooling solutions and small-run bridge tooling before committing to full-scale production.

At Stephens Plastics, we help startups scale smartly by advising on mould design, testing, and production ramp-up. You don’t need millions of units to start seeing returns.

Tooling Considerations: The Foundation of Success

Tooling is the most crucial part of the injection moulding process. Poor tooling leads to inconsistent quality and higher defect rates.

We engineer precision steel moulds built to last for millions of cycles. And with in-house maintenance, we ensure your tooling runs as efficiently on the 1,000,000th unit as it did on the first.

Design for Manufacturability (DFM)

Design plays a huge role in optimising for high-volume injection moulding. At Stephens Plastics, we work closely with clients to refine designs that:

- Reduce material usage.

- Speed up cycle times.

- Minimise post-processing.

- Maximise tooling life.

This collaborative process shortens development cycles and cuts costs before production even begins.

The Environmental Edge

As sustainability becomes a key factor in procurement, injection moulding continues to evolve.

1. Eco-Friendly Materials

We offer biodegradable, recycled, and recyclable material options to help clients reduce their carbon footprint without sacrificing performance.

2. Energy-Efficient Machinery

Our modern machines are energy optimised, using servo-driven hydraulics that reduce power consumption while maintaining speed and accuracy.

Is High-Volume Injection Moulding Future-Proof?

Yes – and here’s why:

- Automation-ready: Easily integrates with robotic systems.

- Data-rich: Real-time monitoring for predictive maintenance and quality control.

- Adaptable: Supports quick changeovers for customisation without sacrificing volume.

These features make it ready for Industry 4.0 and evolving market demands.

Why Choose Stephens Plastics?

Stephens Plastics stands out for three key reasons:

1. Experience and Expertise

With over 30 years in plastic manufacturing, we understand the demands of various industries and ensure every project is built for success.

2. In-House Capabilities

We manage every stage – from toolmaking to testing to packaging. This control ensures quality, consistency, and efficiency.

3. Customer-Centric Solutions

Our team prioritises your objectives, whether you’re scaling up, developing a new product, or improving efficiency.

FAQs About High-Volume Injection Moulding

What’s the lead time for high’volume production?

Typical lead time ranges from 4-12 weeks depending on part complexity, tooling design, and material choice.

What materials can you mould?

We work with a wide range of thermoplastics, including ABS, polycarbonate, polypropylene, nylon, and more.

Can Stephens Plastics handle tight tolerances?

Yes. Our processes are ISO certified and designed to meet high-precision engineering standards.

Conclusion: A Scalable Future with Stephens Plastics

For businesses in the UK and beyond, high-volume injection moulding remains the cornerstone of scalable, economical, and efficient plastic manufacturing. With industry-leading turnaround times, proven tooling design, and a commitment to quality, Stephens Plastics is your ideal partner for moulding for mass production.

From startups to OEMs, we deliver on our promise – consistent, high-quality parts at scale.

Contact Stephens Plastics Today

For a consultation or to discuss your next high-volume injection moulding project, get in touch:

Email: sales@stephensplasticmouldings.co.uk

Phone: 0121 544 5808