High-Speed, High-Precision, Low-Cost Manufacturing – Done in the UK

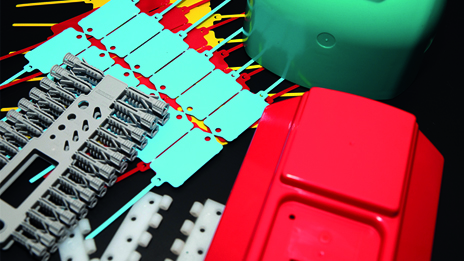

When it comes to producing high volumes of reliable, repeatable plastic parts, injection moulding remains the gold standard. At Stephens Plastic Mouldings, we’ve invested in next-generation machinery, intelligent monitoring systems, and UK-based engineering expertise to help clients scale faster – without compromising on quality or cost.

If your business is seeking mass-production capability that balances speed with accuracy, here’s what you need to know.

Why Choose Plastic Injection Moulding for Mass Production?

1. Scalability Without Compromise

From a few hundred to several million parts, injection moulding delivers consistent, identical results batch after batch. Our facility runs 14 state-of-the-art moulding machines (25T–470T), operated by experienced technicians and monitored by real-time control systems for precise results.

2. Low Cost Per Unit

Once tooling is complete, the per-part cost drops significantly – especially for large volumes. Our use of recycled runners, automated material feeding, and granulators reduces waste and maximises material efficiency. It’s the perfect solution for any high-volume application where budget matters.

3. Precision and Repeatability

Whether you’re producing medical housings, automotive clips, or cosmetic packaging, our advanced tooling and temperature-controlled processes ensure:

- Tight dimensional tolerances.

- Smooth finishes.

- Structural integrity.

- Flawless replication – from part #1 to part #500,000.

4. Versatile Material Options

Stephens Plastic Mouldings can work with a wide range of thermoplastics, from commodity polypropylene and polystyrene to high-performance glass-filled nylons and acetal. We help you select the right polymer based on mechanical needs, regulatory requirements, and cost targets.

5. Fast Turnaround

With tooling and production done in-house, and no reliance on overseas delays, we can deliver lead times as short as 2-4 weeks from sign-off. For many customers, this speed is critical to staying ahead in today’s demanding supply chains.

Our End-to-End Process

At Stephens Plastic, we provide more than just moulding. We support your full journey:

- Design for Manufacture (DFM) reviews.

- Tooling design and manufacture.

- Prototyping and trial tooling.

- Batch testing and quality inspection.

- Assembly, packing and delivery.

This one-stop approach gives you greater control, traceability, and confidence – without managing multiple suppliers.

Who We Serve

- Automotive: High-volume clips, housings, connectors.

- Medical: Single-use diagnostic parts, pump casings.

- Consumer goods: Packaging, containers, functional plastics.

- Industrial OEMs: Heavy-duty brackets, covers, mounts.

Our ISO 9001:2015 certification and commitment to UK-based production make us a trusted choice for regulated and time-sensitive sectors.

FAQs

1. How many parts can Stephens Plastic Mouldings produce per week?

Depending on part size and complexity, we can deliver thousands to hundreds of thousands of parts weekly using our full machine capacity and shift rotation.

2. What’s your minimum order quantity for large batch moulding?

We typically work with batches starting from 1,000 units, but can support smaller volumes for pilot runs or tooling validation.

3. Can you help optimise my part design for mass production?

Yes. We offer free DFM consultations to simplify designs, reduce material use, and improve cycle times before tooling begins.

4. Do you recycle excess plastic or support sustainable production?

Absolutely. We use granulators to reprocess material waste on-site and offer options for recycled polymers to meet environmental targets.

5. How long does it take from tooling approval to first delivery?

Standard lead time is 2-6 weeks, depending on tool complexity and order volume. We also offer expedited production for urgent projects.

Work With a Trusted UK Partner for Scalable Plastic Moulding

With decades of experience and a facility built for speed and accuracy, Stephens Plastic Mouldings is the go-to partner for mass production in the UK. Whether you’re producing 10,000 clips or 250,000 diagnostic enclosures, our processes are tuned for volume, value, and verification.

To request a quote Or arrange a free consultation with our technical team

Contact Stephens Plastics Today

Email: sales@stephensplasticmouldings.co.uk

Phone: 0121 544 5808