Choosing the Right Plastic Moulder in Birmingham: A Comprehensive Guide

12 December 2024

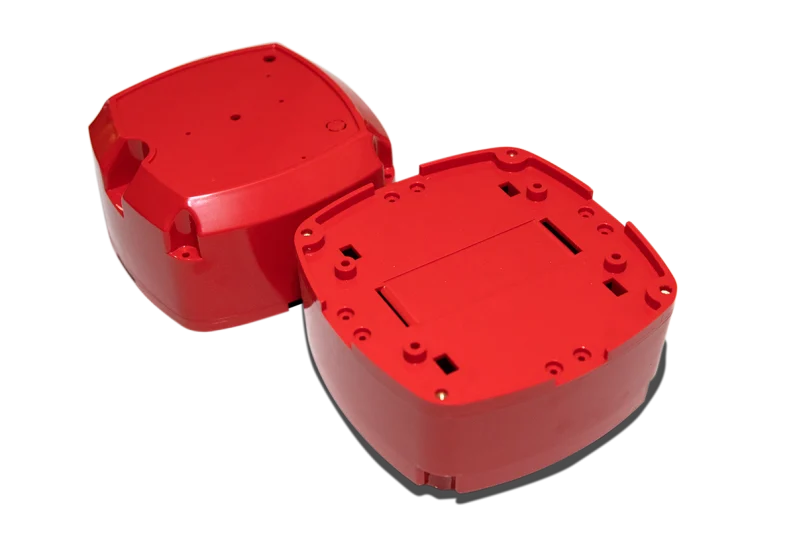

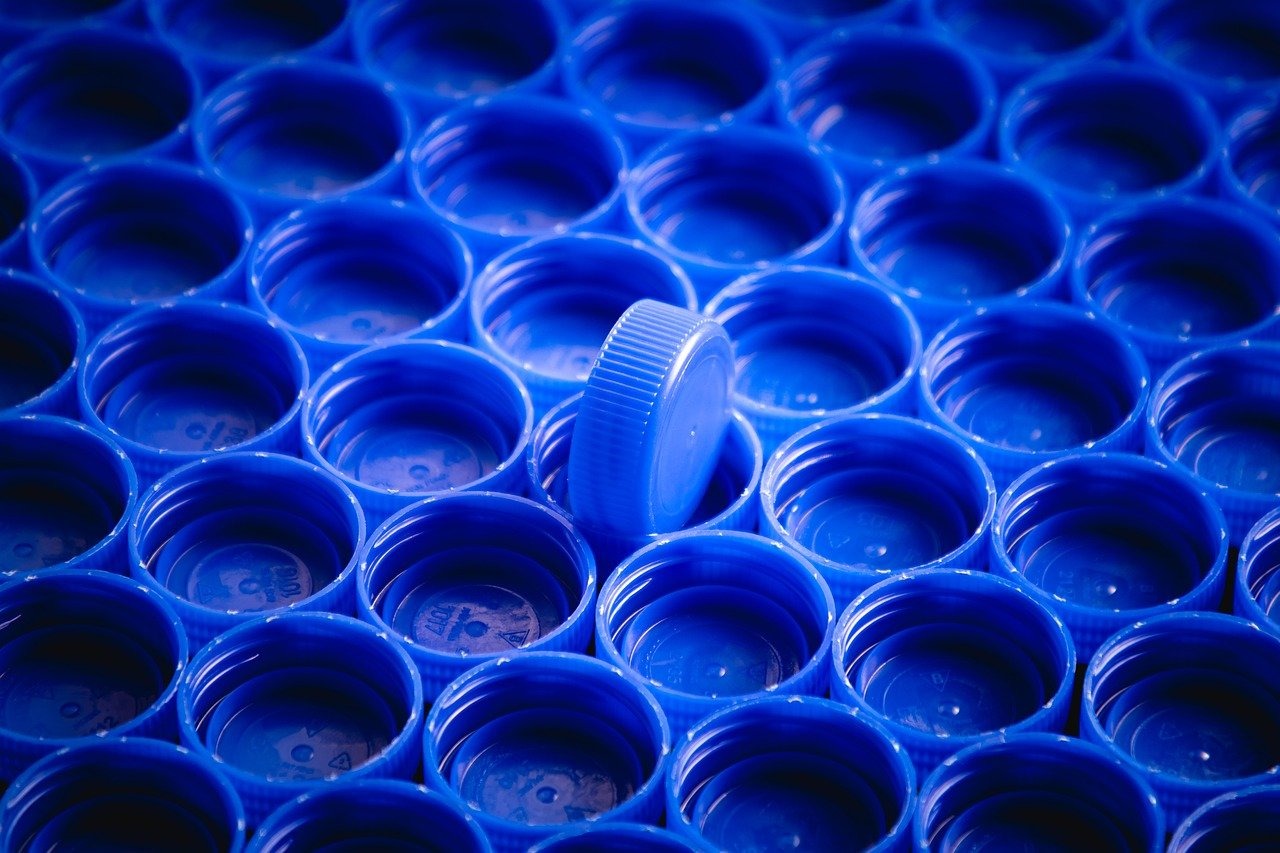

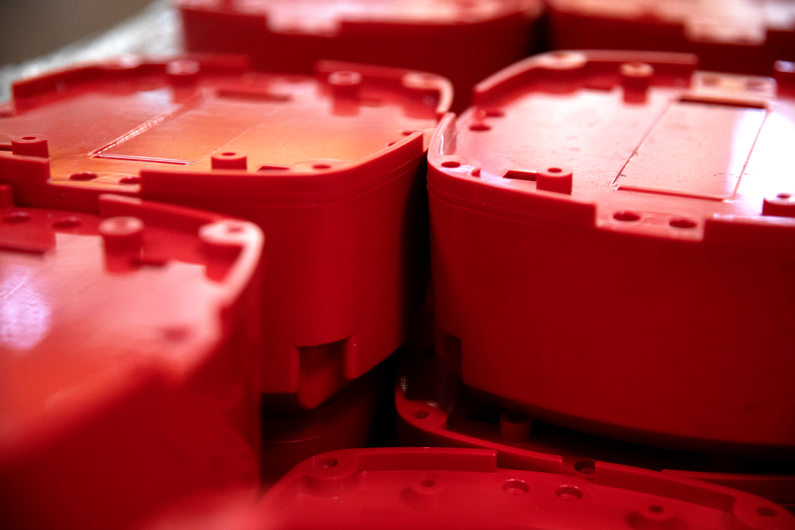

Finding the right plastic moulder in Birmingham is crucial to the success of your manufacturing project. With so many options available, it can feel overwhelming to select a partner that aligns with your needs. At Stephens Plastic Mouldings, we aim to simplify this decision by offering a guide on what to consider when choosing the […]