Plastic Injection Moulding in Product Development

11 February 2026

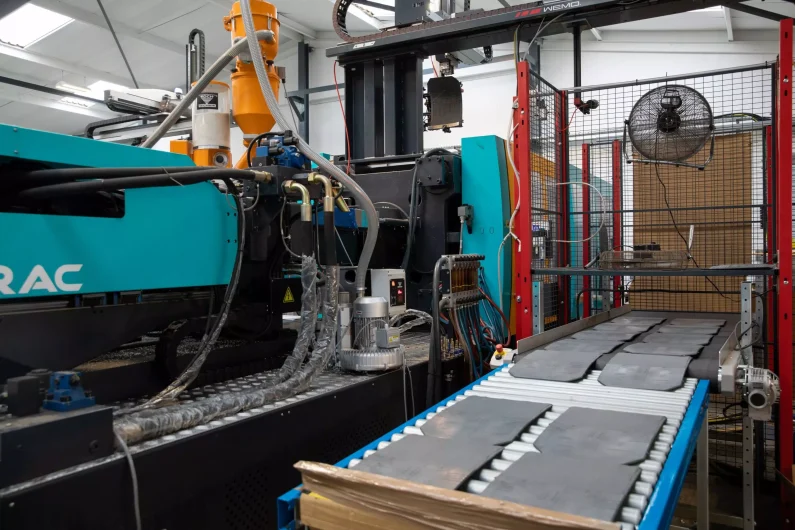

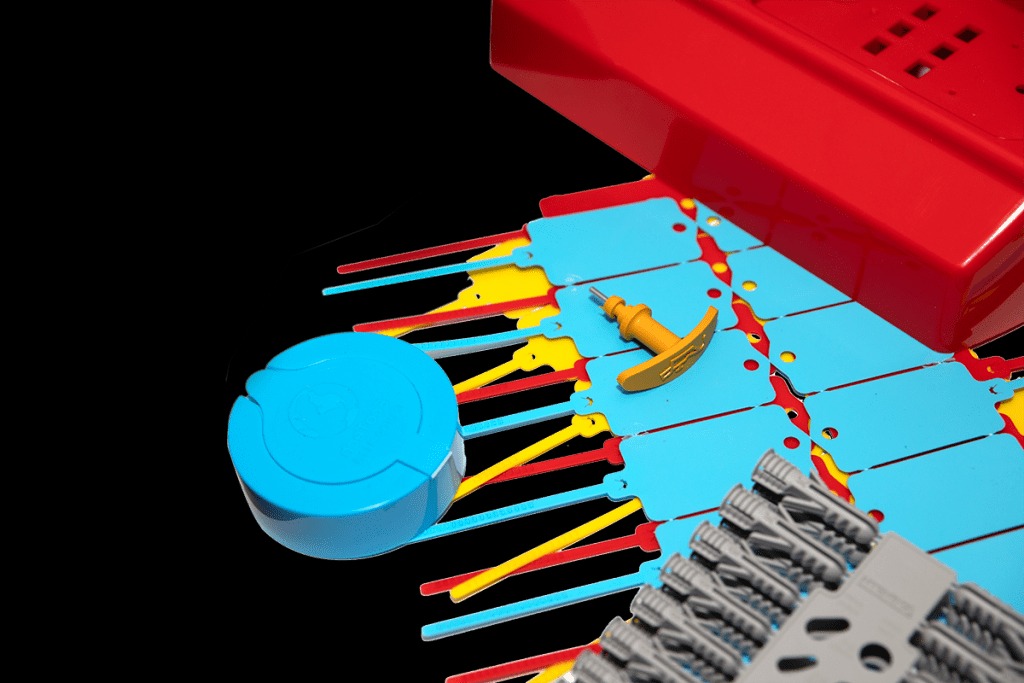

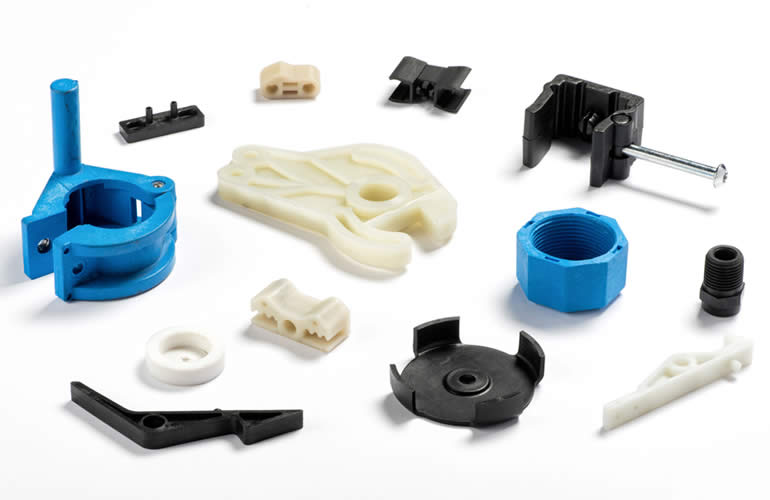

Plastic Injection Moulding: The Engine Behind Modern Product Development Product development in 2026 is defined by three pressures: Faster time-to-market. Greater design customisation. Lower lifecycle production costs. Plastic injection moulding has become central to achieving all three. At Stephens Plastic Mouldings, we support product developers by integrating design validation, prototype production and scalable injection moulding […]