Plastic Injection Moulding Walsall

Local Service. National Capability. Global-Standard Results

Walsall has long been a cornerstone of UK manufacturing. Today, the town continues to evolve – supporting sectors from metalwork and industrial tooling to modern packaging and consumer innovation. Stephens Plastic Mouldings is proud to support as a plastic moulding company for Walsall businesses.

We offer end-to-end production support—from initial design through to moulding, finishing, and assembly – all managed from our fully equipped West Midlands facility. Whether you’re supplying the construction sector, launching a product line, or replacing hard-to-source legacy components, we help you move quickly, stay flexible, and manufacture smarter.

Injection Moulding for Walsall Businesses

Our clients in Walsall come to us for:

- No minimum order requirements.

- Fast tooling and short production lead times.

- ISO 9001:2015 quality assurance.

- Local access and responsive communication.

- Materials support for regulated and technical industries.

We work closely with Walsall-based OEMs, product designers, engineers, and procurement teams who value dependability, personal service, and parts that just work.

What We Offer

| Service | What You Get |

|---|---|

| Design Assistance | CAD refinement, part evaluation, and manufacturability advice. |

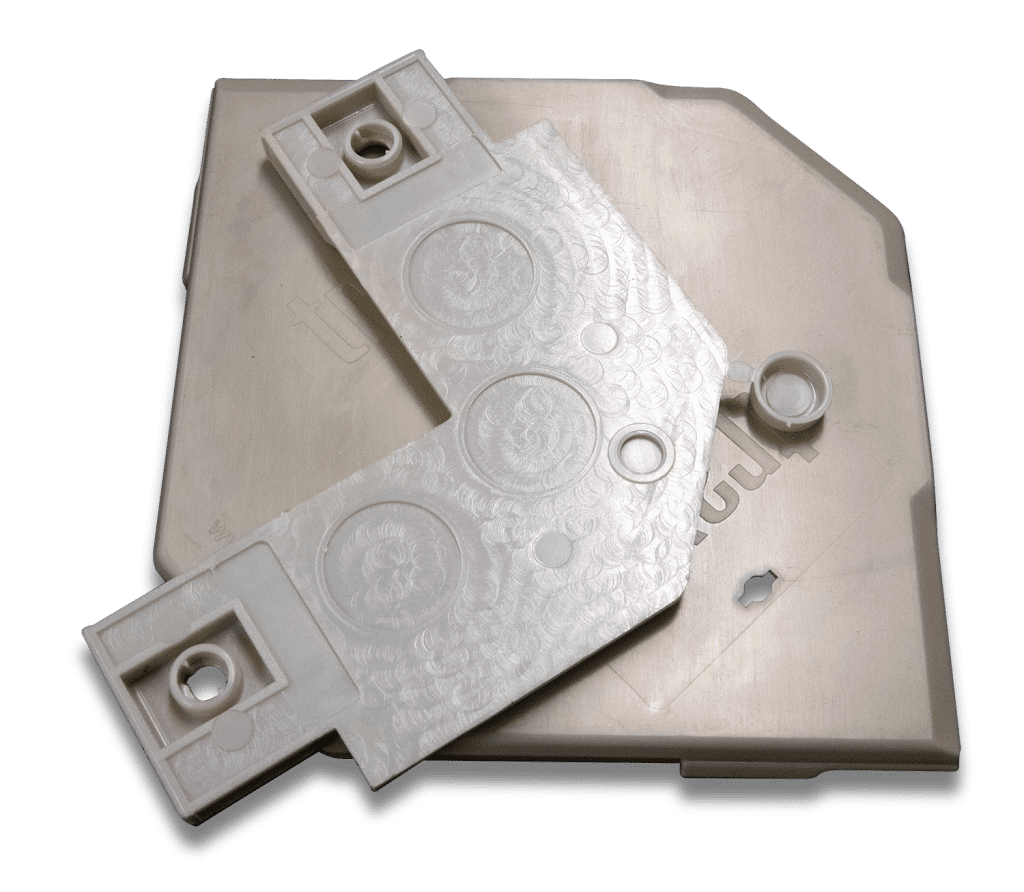

| Tooling (In-House) | Aluminium or steel moulds, built fast and made to last. |

| Flexible Production | No MOQs – ideal for prototypes, small batches, or large-scale supply. |

| Specialist Moulding | Insert moulding, multi-shot, and overmoulded components. |

| Assembly & Finishing | Trimming, welding, printing, and ready-for-distribution kitting. |

| Material Expertise | Food-grade, flame-retardant, medical, recycled, and more. |

Why Choose Stephens Plastic Mouldings?

1. Built on Experience. Driven by Precision

With over two decades of plastic injection moulding expertise, we’ve supported hundreds of UK projects across multiple industries. We understand the pressure that Walsall’s supply chains operate under – and we bring the experience and problem – solving mindset to match.

Our engineers have dealt with the tightest tolerances, fastest lead times, and most demanding applications – and we apply that knowledge to every new project.

2. Local to Walsall, Trusted Nationally

Our West Midlands facility is just a short distance from Walsall, which means we can deliver quickly, consult in person, and offer more responsive support than distant suppliers.

All production is based in the UK, allowing you to avoid international shipping delays, quality inconsistencies, or communication issues.

3. A True Manufacturing Partnership

We see our clients as long-term partners. You’ll have a single point of contact, open access to our team, and regular project updates to keep your production moving.

We’re here to offer honest input, adapt when needed, and ensure you’re supported from your first prototype to your last shipment.

4. Innovation That Supports Growth

Whether you’re introducing a new product or refining an existing one, we help you bring it to life with practical design support, smart tooling, and scalable production. We also invest in the latest moulding technology to ensure you can benefit from advanced techniques – like overmoulding, insert moulding, and custom texturing.

We don’t just make parts – we help you improve them.

5. Dependable Supply You Can Count On

We know your deadlines matter. That’s why we run a tightly managed production schedule, offer clear turnaround times, and hold ourselves accountable to every delivery.

Our ISO-certified quality checks, materials traceability, and production reporting help you plan with confidence and protect your reputation.

Supporting Key Industries in Walsall

Walsall’s manufacturers are diverse, and so is our experience.

We support companies working in:

Functional plastic parts for mechanical assemblies, control housings, handles, clips, brackets, and machine panels.

Plastic caps, containers, closures, and retail-ready trays - produced from food-safe materials and available in brand-matched finishes.

Custom-moulded inserts, guides, safety components, and protective elements for heavy-use environments.

Moulded cable channels, sensor housings, enclosures, and technical parts for sensitive electronic and test equipment.

Materials Made to Fit Your Needs

We help you choose the right polymer based on performance, application, and compliance needs.

Common materials include:

- Polypropylene, ABS, Nylon, Polycarbonate.

- TPE/TPU (for grip, flexibility, or sealing).

- High-impact and UV-stable resins.

- Flame-retardant or anti-static (ESD-safe).

- Bioplastics and regrind content for sustainability.

- Medical- and food-compliant grades with certification.

We source from reputable UK and European suppliers to ensure full material traceability and consistency batch after batch.

FAQs

Yes. We regularly serve clients across Walsall and the wider Black Country area, with reliable local delivery.

Standard tooling can be completed in 3 - 6 weeks. Repeat production runs often ship within days once tooling is approved.

Yes - we offer design-for-manufacture input, prototyping support, and help choosing the right material for your goals.

Yes. We operate under ISO 9001:2015, with full documentation, traceability, and batch tracking.

Absolutely. We offer prototype tooling and sample runs so you can validate your part before scaling up.

Let’s Start Your Project

If you’re based in Walsall and need a dependable injection moulding partner who values your time, your project, and your standards – talk to Stephens Plastic Mouldings.

– Made in the Midlands | Flexible Volumes | ISO 9001:2015.

– From Tooling to Delivery, We’ve Got You Covered.

Request a free quote OR

Get in Touch today

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.