Plastic Injection Moulding West Midlands

Are you searching for a plastic injection moulding specialist in the West Midlands with in-depth knowledge and a proven track record?

Do you need a well-established team to handle your injection moulding project from concept to production, with quality and reliability assured?

At Stephens Plastic Mouldings,

We are proud to be the West Midlands’ premier plastic injection moulding company. With our main headquarters in the heart of the region, we offer local businesses and national clients the full package – handling everything from initial design and prototypes through to high-volume manufacturing and assembly under one roof.

Our team of experts brings over two decades of experience, ensuring your project is executed with precision, efficiency, and the highest standards of quality. As a leading injection moulding manufacturer, we combine technical expertise with outstanding customer service. You can rely on us for comprehensive project management – including design engineering, in-house toolmaking, material selection, production, and strict quality control.

We work closely with you at every step to bring your product ideas to life, on time and on budget. Situated in the West Midlands (the historic heart of UK manufacturing), our facility blends the region’s rich industrial heritage with cutting-edge technology to deliver outstanding results for our clients.

If you require case studies and referrals from businesses in the region, please don’t hesitate to contact us. As you can appreciate, in many cases NDAs are in place which limit the public citation of customers; however, we are able to discuss relevant case studies across most regions and industry sectors on a confidential basis.

- Competitive Pricing: Cost-effective solutions tailored to your budget without compromising on quality. We optimize designs and processes to save you money while delivering excellent products.

- UK-Based Manufacturer: All production is done at our West Midlands facility. This offers you local support, fast turnaround times, and easy communication – a true local partner with national reach.

- Complete Service: We handle everything from CAD design and prototyping to tooling, moulding, and even assembly and packaging. This one-stop-shop approach streamlines your supply chain and ensures accountability at every stage.

- ISO 9001 Certified Quality: Our ISO 9001-certified quality management system means every part we produce undergoes rigorous checks. You get consistent, high-quality results with full traceability and documentation.

- Free Trial Tooling: Not sure if your design is perfect? We offer trial tooling and sample runs to prove out and refine your product before full production. You get the exact results you need, with no risk.

What Is Plastic Injection Moulding?

Plastic injection moulding is a manufacturing process used to create a vast range of plastic parts and products by injecting molten plastic material into a precise mould. In this process, small plastic pellets (thermoplastic polymers) are heated in an injection moulding machine until they melt, then the molten plastic is injected under pressure into a custom-tooled mould cavity.

Once the plastic cools and solidifies, it takes on the exact shape of the mould, producing a durable finished component with fine detail and a consistent finish. This technique is extremely versatile and efficient. It can produce everything from one-off prototype pieces to thousands or even millions of identical parts with excellent repeatability. The injection moulding process allows manufacturers to achieve complex shapes, high levels of precision, and smooth surfaces with minimal post-processing. It’s the go-to method for making many everyday items and critical components across various industries, thanks to its reliability and scalability.

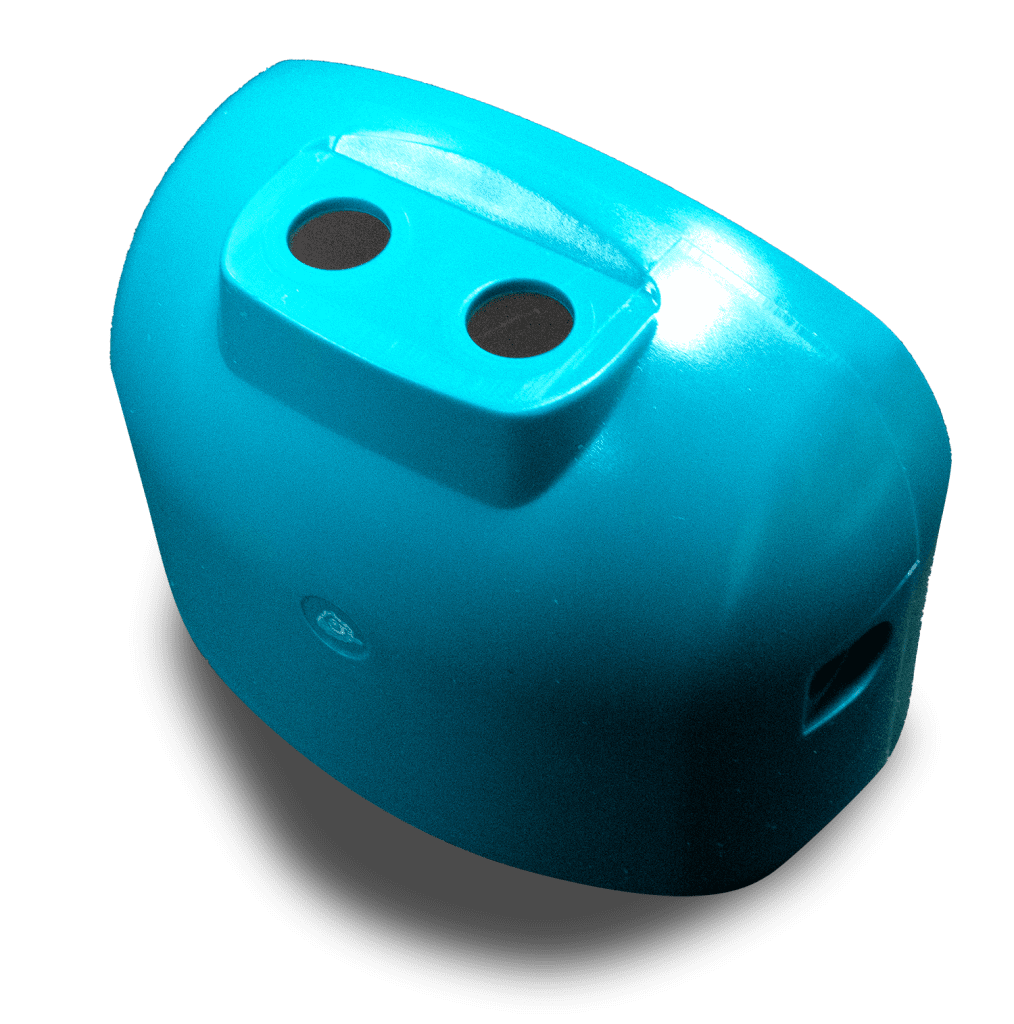

For example, many items you use daily are made via injection moulding: bottle caps, food containers, automotive interior panels, electrical housings, mobile phone cases, medical device components, and much more. The process ensures each piece meets exact specifications, making it ideal for both common consumer products and specialized industrial parts. By using high-quality moulds and materials, injection moulding produces parts that are uniform and meet strict quality standards piece after piece.

In a recent research exercise Stephens Plastic was found to be a market leader in the West Midlands beating competitors such as Barkley Plastics and MGS Technical Plastics

| Company | Key Service Focus & Position | Strengths | Weaknesses | Opportunities | Threats | Leader/Follower |

|---|---|---|---|---|---|---|

| Stephens Plastic | Precision plastic injection moulding with full-service support. | In-house tooling, design & prototyping; end-to-end manufacturing; ISO certified; quick turnarounds. | Online presence though growing quickly ; SEO visibility still developing. | Growth in medical, automotive, and consumer goods sectors; reshoring trends. | Low-cost overseas moulders; rising raw material costs; UK economic uncertainty. | Market Leader. |

| Barkley Plastics | Technical injection moulding and tooling. | Strong in automotive sector; in-house toolroom; decades of experience. | Heavy reliance on automotive; less flexible for small or diverse batch sizes. | Diversification into EV, consumer electronics, and sustainable materials. | Automotive downturn; Brexit-related export pressures. | Market Follower. |

| MGS Technical Plastics | Technical moulding with post-moulding services. | Strong case studies; focus on engineering-led solutions. | Distance from West Midlands; limited appeal for short-run or prototyping clients. | Partnering with OEMs on sustainability and innovation. | Increased automation reducing service differentiation. | Market Follower. |

| Rutland Plastics | Complex technical moulding; full design-to-delivery. | In-house tooling and 3D printing; known for quality and technical complexity. | Higher cost base; slow to scale rapidly. | Demand for UK-based reshoring and quality over price. | Cheaper EU and Asian providers offering ‘good enough’ quality. | Market Follower. |

| Malton Plastics | Injection moulding with white-label services. | Experience with branding, packaging, and retail-ready plastics. | Less visible thought leadership or innovation content. | Expanding into consumer goods and retail sectors. | Innovation gap vs high-tech moulders; squeezed by price wars. | Market Follower. |

| CJ Tool & Mouldings | Toolmaking and injection moulding. | One-stop-shop model; investment in automation and robotics. | Smaller scale vs nationals; narrow appeal outside Midlands. | Scaling with automation; contract manufacturing for D2C startups. | Consolidation of suppliers; rising lead times due to tooling bottlenecks. | Market Follower. |

| Tex Plastics | Lean manufacturing for plastic components. | Focused on speed, lean cost structure, and repeatability. | Lower engineering support than some full-service competitors. | Fit for mass production and automotive clients. | Less suitable for smaller batch or highly engineered components. | Market Follower. |

| Cornelius Electronics | Sub-assembly and plastic mouldings for electronics. | Integration of plastics into broader electronic builds. | Plastics is a side service, not core offering. | Electronics sector growth; bundling value-added services. | Not a true specialist; not focused on standalone plastic moulding. | Market Follower. |

Our Plastic Injection Moulding Services

We provide end-to-end injection moulding services to streamline your project and ensure

Superior Results:

Whether you have a rough idea or complete CAD drawings, our design team can help refine your product for optimal manufacturability. We offer Design for Manufacture (DFM) support, using CAD/CAM software to develop efficient mould designs and 3D prototypes. By fine-tuning the design early, we save you time and cost later on and make sure the part will perform as needed.

High-quality tooling is the foundation of successful injection moulding. Our skilled toolmakers produce precision injection moulding moulds (dies) in steel or aluminium, tailored to your design. We advise on the best tooling material depending on the volume and lifespan you require - for example, aluminium tools for cost-effective prototyping or steel tools for long-running production. Each mould is crafted with care to ensure durability, accuracy, and a perfect fit for our machines.

Before full production, we can create sample parts or small prototype runs for testing and validation. This trial phase lets you evaluate the look, feel, and function of the component in real life. We’ll work with you to adjust any details until you are completely satisfied. Our free trial tooling option allows you to perfect your design risk-free, ensuring confidence when moving to mass production.

Whether you need a short run of a few hundred units or mass production of tens of thousands, we have you covered. Our modern injection moulding machines can handle a range of part sizes and complexities with ease. We schedule and manage the production efficiently to meet your deadlines. We also specialise in advanced moulding techniques: for example, overmoulding (moulding plastic over an existing part or substrate for a two-part assembly or added grip) and insert moulding (encapsulating metal or electronic components inside plastic). These capabilities allow us to produce complex, multi-material components in one streamlined process.

Our service doesn’t end when the parts come out of the press. We offer secondary operations such as trimming, drilling, tapping, ultrasonic welding, and assembly of multiple components if your product requires it. Finally, we can package and label your parts as needed. You'll receive finished components or assembled products ready for distribution or sale. This end-to-end solution simplifies your supply chain and ensures accountability, as you're dealing with one trusted supplier from start to finish.

Industries We Serve

As a West Midlands-based manufacturer, Stephens Plastic Mouldings proudly supports a wide range of industries and sectors across the region and the UK.

Our injection moulding expertise is applied in many fields, including:

- Automotive: We produce high-precision, durable plastic parts for vehicles – from interior trim pieces and dashboard components to under-the-hood clips and engine bay parts. The West Midlands’ strong automotive industry relies on quality components, and we deliver parts that meet strict automotive standards for safety and performance.

- Electronics & Electrical: We manufacture enclosures, switch housings, connectors, and insulating components for electronics. These parts require exact specifications and quality materials to protect sensitive electronics. Our moulded products can be found in consumer electronics, appliances, and industrial electrical systems.

- Consumer Products: From kitchen appliances to furniture fittings, toys, and sports equipment, we supply plastic components that end up in everyday consumer goods. We understand the need for attractive finishes and robust build in consumer products, and we can also incorporate branding or custom colors into your moulded parts.

- Construction & Industrial Engineering: We mould parts used in construction equipment, plumbing and heating systems, and general industrial machinery. This includes items like pipe fittings, panels, tool casings, and fasteners. These applications demand plastics that can withstand heavy use and challenging environments – a challenge we meet through proper material selection and design.

- Medical & Healthcare: For clients in the medical sector, we produce components such as medical device housings, surgical tool parts, laboratory equipment pieces, and packaging for healthcare products. We pay extra attention to material biocompatibility, cleanliness, and precision for these critical applications. Our ISO-certified processes help ensure compliance with healthcare standards.

- Lighting & Electrical Fixtures: We manufacture plastic lenses, diffusers, light housing units, and fixture components for the lighting industry. These parts often require excellent clarity or heat resistance, which we achieve using the right polymer (such as polycarbonate or acrylic) and careful moulding conditions.

- Research & Development (Prototyping): We assist innovators and R&D departments by producing prototypes and low-volume runs for testing new designs. By partnering with us, research teams in the West Midlands can quickly iterate and refine their product concepts using real injection-moulded parts, accelerating the development cycle.

No matter your industry, we have likely worked on a similar application or can apply our broad experience to meet your specific needs.

Our adaptable approach and deep understanding of various sector requirements make us a versatile partner for any business that needs custom plastic parts.

Materials We Work With

Selecting the right material is crucial for any injection moulding project. Different applications demand different properties – whether it’s strength, flexibility, heat resistance, clarity, or cost-effectiveness. At Stephens Plastic Mouldings, we work with a wide variety of thermoplastic resins and will help you choose the optimal material for your product.

We commonly mould using:

1. Commodity Thermoplastics

Polypropylene (PP), Polyethylene (PE) – including HDPE/LDPE – and Polystyrene (PS) are versatile plastics ideal for general-purpose parts and consumer goods. They offer good processability and affordability for high-volume production.

2. Engineering Plastics

For more demanding applications, we use materials like Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), Nylon (Polyamide PA6/PA66), and Acrylic (PMMA). These plastics provide enhanced strength, rigidity, impact resistance, or optical properties. For example, ABS and Polycarbonate are great for electronic housings and automotive parts due to their toughness, while PMMA (acrylic) is chosen for its glass-like clarity in lenses and displays.

3. High-Performance Polymers

We also handle specialty plastics such as Polyacetals (POM, e.g. Delrin), Polyurethane (PU), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), and glass or fiber-reinforced grades (e.g. glass-filled nylon or polypropylene). These materials are used when specific performance characteristics are needed – like low friction, chemical resistance, high temperature endurance, or extra stiffness. If your project requires a plastic that can take extreme conditions or meet stringent standards, we likely have experience with it.

4. Recycled & Sustainable Materials

Wherever possible, we can incorporate regrind (recycled plastic) or biodegradable plastics to support your sustainability goals. Using recycled material can be cost-effective and eco-friendly for suitable applications. We are happy to discuss material options that reduce environmental impact while still meeting your requirements.

Our experts stay up-to-date with the latest material innovations in the plastics industry.

We source high-grade, certified materials and can even arrange for custom compounding (adding UV stabilizers, flame retardants, color pigments, etc.) to get the exact properties you need. During the planning stage, we will recommend the best material choices based on the product’s function, the working environment, regulatory requirements, and your budget.

Not sure which plastic is right for your product?

We’ll guide you. Part of our service is to explain the pros and cons of different materials in plain language, so you can make an informed decision. The result is a product that not only performs excellently but is also optimized for cost and manufacturability.

Applications of Our Injection Moulding

Our injection moulding capabilities cater to an incredibly broad range of applications. If it’s made of plastic, the chances are we can mould it! We have produced everything from simple everyday items to complex technical components.

Here are just a few examples of what we can create:

We excel at moulding tiny parts like gears, clips, caps, fasteners, and connectors that require fine details and tight tolerances. These are used in products like electronics, appliances, and automotive systems. Even minute parts come out accurate and consistent with our process.

Many common products are made of multiple medium-sized plastic parts. We manufacture items such as handles, knobs, casings for power tools or gadgets, containers and boxes, plumbing fittings, and appliance components. These parts often need to be strong and dimensionally stable - qualities we achieve through proper design and material selection.

With our robust machinery, we can handle fairly large mouldings too. This includes things like automotive bumpers or dashboard panels, larger enclosures, furniture pieces (chair shells, table tops), or industrial machine housings. (The exact size limit depends on our press capacity, but we accommodate a wide range of sizes.) We ensure even big parts are moulded with precision, avoiding warping or defects.

Some applications require combining materials – for example, adding a soft grip to a hard plastic tool handle, or encasing a metal insert within a plastic part (like threaded inserts, bearings, or electronic sensors). Our overmoulding and insert moulding capabilities allow for these advanced applications. We can produce multi-material components in one go, which improves bond strength and reduces assembly steps.

Injection moulding isn’t only for mass production. We frequently help customers who need a prototype or a limited batch of parts to test a new design. Using quick tooling methods and our experience, we can deliver prototype-quality parts in the actual production material, which is invaluable for functional testing and marketing samples. This way, you get to see and feel the real thing before committing to full production.

This versatility means that no project is too simple or too complex for us. We approach each application with the same level of dedication and attention to detail. Whether you require a durable part that must withstand heat and stress, a cosmetic piece with a flawless surface, or a clear plastic component with optical clarity, we have the know-how to make it happen. Our team loves a challenge and is always ready to explore new applications of injection moulding to meet our clients’ unique goals.

Why Choose Stephens Plastic Mouldings?

In a region filled with manufacturing companies, why choose Stephens Plastic Mouldings as your West Midlands injection moulding partner? Here are some compelling reasons: Experience & Expertise: We bring a wealth of experience and know-how to every project. Founded over 20 years ago, our company has honed its skills by delivering successful outcomes for countless projects and clients. Our engineers and technicians are highly trained and passionate about plastics – we stay on the cutting edge of moulding technology, machinery, and design techniques. This means you get access to the latest and most efficient solutions for your manufacturing needs. When you work with us, you’re tapping into a knowledge base built over decades of hard work and continuous improvement. Quality & Reliability: Quality is at the core of everything we do.

As mentioned, we are ISO 9001 certified, which reflects our commitment to rigorous quality control and traceability. From initial material inspection to final dimensional checks, we have robust procedures to ensure every part meets specification. We’re also serious about reliability – we know that your production schedule or product launch can depend on our delivery. That’s why we maintain equipment proactively to avoid downtime, and we schedule our production carefully to meet agreed deadlines. Our clients trust us to get the job done right and on time, and we take that responsibility personally.

Many of our partnerships span years; we’re proud that customers return to us for project after project, which speaks to the trust and consistency we have earned. Comprehensive, Customer-Focused Service: When you choose Stephens, you’re not just getting a supplier – you’re gaining a partner. We offer the personal touch of a local business combined with the capabilities of a larger enterprise. Being based in the West Midlands means we are easily accessible for face-to-face meetings, on-site visits, or just a quick phone call to discuss ideas. Our team is friendly, approachable, and genuinely invested in your success. We listen carefully to your requirements and provide honest guidance. If there’s a more cost-effective or better approach to achieve what you need, we’ll tell you. If you have concerns or changes, we respond flexibly. In short, your goals become our goals. This customer-centric ethos ensures a smooth, collaborative process and results that align with your vision.

Advanced Technology & Continuous Improvement:

Manufacturing is an ever-evolving field, and we’re committed to staying ahead of the curve. We invest in modern injection moulding machines, robotics, and automation where beneficial, to improve efficiency and repeatability. We also regularly train our staff on new materials and techniques. By embracing innovation, we can offer you improved lead times, lower scrap rates, and competitive pricing. We also love finding creative solutions to challenging projects – whether it’s a complex geometry that needs a clever tooling approach or a unique material that needs fine-tuned process settings, our technical team thrives on innovation. When you bring a project to us, you can trust that we’ll apply the best of today’s technology and thinking to deliver an optimal outcome.

Beyond these tangible benefits, we believe in building an emotional connection and true partnership with our clients. We understand that choosing a manufacturing partner is about more than just capabilities and price; it’s about finding a team that genuinely understands and cares about your needs.

We provide:

- Certainty (Reliability): You can count on us. We provide a sense of certainty by being reliable and consistent in our work. Deadlines are met and promises kept – giving you peace of mind that your project is in safe hands from start to finish.

- Variety (Flexibility & Choice): We offer flexibility to accommodate your specific needs. Every project is unique, and we’re adaptable in our approach – whether that means handling a variety of part designs, adjusting production volumes, or finding creative ways to solve a problem. This willingness to embrace variety ensures you get a solution tailored to you, not a one-size-fits-all service.

- Significance (Making You a Priority): We make sure you feel valued. No matter the size of your business or order, you are important to us. Our team gives each project the attention it deserves and takes pride in helping bring your important products to life. Your success adds to our legacy, so we truly care about making your project successful and significant.

- Connection (Strong Partnerships): We aim to build a real connection through honest communication and collaboration. We see our clients as partners and often an extension of our team. By fostering a friendly, open dialogue, we ensure you always feel comfortable reaching out, asking questions, and providing feedback. This close partnership means we’re aligned with your objectives and can adjust quickly to your needs.

- Growth: We support your growth and ours goes hand-in-hand. When you’re ready to scale up, we’ll be there to ramp up production. If you’re developing new products, we’ll be ready with prototyping and design input. We love seeing our clients grow, and we continually expand our capabilities to make sure we can support new opportunities. Additionally, we seek growth in our own knowledge and skills, so we can bring you new ideas, improved processes, and cost savings over time – helping you stay competitive.

- Contribution (Giving Back & Ethical Practice): We believe in contributing positively – to your business, to the community, and to the environment. By helping you manufacture great products, we contribute to your customers’ satisfaction and your business success. We also take environmental responsibility seriously: we recycle scrap material, use energy-efficient equipment, and can advise on eco-friendly material choices. Furthermore, as a West Midlands employer, we contribute to the local economy and support manufacturing heritage in our region. This sense of purpose drives us to be the best at what we do, knowing that our work benefits more than just our bottom line.

In summary

Choosing Stephens Plastic Mouldings means choosing experience, quality, and a dedicated partner who genuinely cares about meeting your needs. We don’t just make plastic parts – we help build businesses, support innovation, and create lasting relationships. Our aim is to deliver an exceptional experience as well as exceptional products, so you feel confident and even excited to be working with us. Let us take the stress out of your injection moulding projects and turn your ideas into tangible success.

FAQs

Plastic injection moulding is a manufacturing process where melted plastic is injected into a mould to form specific shapes. It’s used to mass-produce a huge variety of items – from simple objects like bottle caps and toys to complex components like car dashboards, medical device parts, and electronic housings. The process is highly versatile and efficient, making it ideal for producing large quantities of consistent and precise parts. If you look around your home or office, many plastic items you see were likely made by injection moulding.

A wide range of thermoplastic polymers can be injection moulded. Common materials include polypropylene, polyethylene, ABS, polycarbonate, nylon, polystyrene, and acrylic, to name a few. Each material has different properties – some are very tough, some are flexible, some are heat-resistant, etc. The choice of material depends on what characteristics you need in your part (for example, does it need to withstand heat or impact? Does it need to be food-safe or have a glossy finish?). At Stephens Plastic Mouldings, we help you select the best material for your project and can work with specialty plastics or even recycled materials if required.

Yes, injection moulding can absolutely be used for low-volume production and prototypes - especially with our approach. Traditionally, the cost of making a mould tool is a big investment, which is why injection moulding is often associated with mass production. However, we offer cost-effective tooling options for smaller runs and even trial tooling for prototyping. This means you can get a small batch (tens or hundreds of parts) without an exorbitant cost. It’s a great way to test a new product in the real world with the exact materials and process that would be used for full production. Once you're satisfied and demand grows, we can then scale up to high-volume production using more robust tooling. We’re happy to support projects at any stage - from one-off prototypes to large-scale manufacturing.

Injection moulding is one of the most cost-effective ways to manufacture plastic parts at scale. While there is an upfront cost to create the mould (tooling), once that’s in place, the cost per part drops significantly for larger quantities. The process is very efficient – cycle times (the time to produce each part) can be just seconds, and modern machines can run with minimal supervision, which keeps labor costs down. Additionally, material waste is low because excess plastic can often be recycled or re-ground. For high volumes, the economies of scale make injection moulding much cheaper per unit than processes like 3D printing or CNC machining. Even for moderate volumes, we work with you to ensure the overall project is economical. We design tooling to be durable for long runs and optimize the moulding process to minimize scrap, all of which improves cost efficiency. In short, if you need more than a handful of identical parts, injection moulding usually offers great value. Our team can provide a detailed quote and cost breakdown so you can see how it would work for your specific project.

Working with a local company like Stephens Plastic Mouldings offers several advantages. First, convenience and communication – being in the West Midlands, we’re in easy reach for companies in the region, which means you can have in-person meetings, on-site visits, or even drop by to see a production run if you want. This close proximity often leads to better collaboration and quicker problem-solving. Second, you’ll benefit from faster turnaround and flexible service. Without the delays of overseas shipping or time zone issues, we can respond quickly to your needs and adjust schedules to meet urgent deadlines. Third, supporting a local business contributes to the regional economy and reduces the carbon footprint associated with long-distance logistics. Lastly, we combine that local touch with top-tier expertise – you don’t have to sacrifice quality or capabilities by staying local. Stephens has advanced machinery and an experienced team, so you get the best of both worlds: world-class injection moulding services with the accessibility of a hometown provider. Many West Midlands businesses find this extremely valuable for building a reliable supply chain.

It’s easy to get started. Simply get in touch with us via phone or email (see our contact details below) to discuss your project. You don’t need to have everything figured out – we often guide clients from the very early stages. Ideally, you can share any product designs, drawings, or even sketches you have. We will talk through your goals, quantity needs, and any material or function requirements. From there, our team can provide initial advice and a free, no-obligation quote. If you decide to proceed, we’ll move into the design refinement and tooling phase, keeping you informed at each step. We can also sign any necessary NDAs if your idea is confidential. Essentially, just reach out to us with your idea or request, and our friendly experts will lead you through the process from concept to finished product. We make the journey of bringing a plastic product to life straightforward and collaborative.

Get Started Today

Ready to turn your idea into reality with a trusted West Midlands injection moulding partner?

We’d love to hear from you.

Contact Stephens Plastic Mouldings

Today for a free consultation or to request a quote.

Our knowledgeable and approachable team is here to answer your questions and guide you through the next steps of your project.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We also welcome you to visit our facility and see our operation first-hand. If you’d like to arrange a site visit or a factory tour, just let us know – we’re proud to show you how we work. Stephens Plastic Mouldings is committed to helping businesses in the West Midlands and beyond bring their plastic products from concept to production.

Get in touch With us today, and let’s make your project a success!

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.