Plastic Injection Moulding South West

Precision Plastic Injection Moulding for South West Industry

Stephens Plastic Mouldings is a leading UK manufacturer supplying plastic injection moulding services to businesses across the South West. Whether you’re in Bristol, Exeter, Swindon, Plymouth, or the wider region, we offer end-to-end production of injection moulded parts – from concept design to post-mould assembly.

Our ISO 9001-certified systems, in-house toolmaking, and flexible manufacturing options help you deliver products faster and with greater confidence. We support both low- and high-volume runs, enabling startups, OEMs, and established manufacturers to scale reliably.

We understand the importance of proven experience when selecting a manufacturing partner. Although many of our client relationships are protected by NDAs, we can discuss relevant case studies and sector experience across a wide range of regions in a confidential conversation.

Trusted Partner for South West Manufacturing

From aerospace in Bristol to marine and packaging sectors in Plymouth, the South West has long been a hub for technical innovation. Stephens Plastic supports this growth by providing consistent, UK-manufactured plastic parts that meet strict performance and compliance requirements.

We serve a range of industries including:

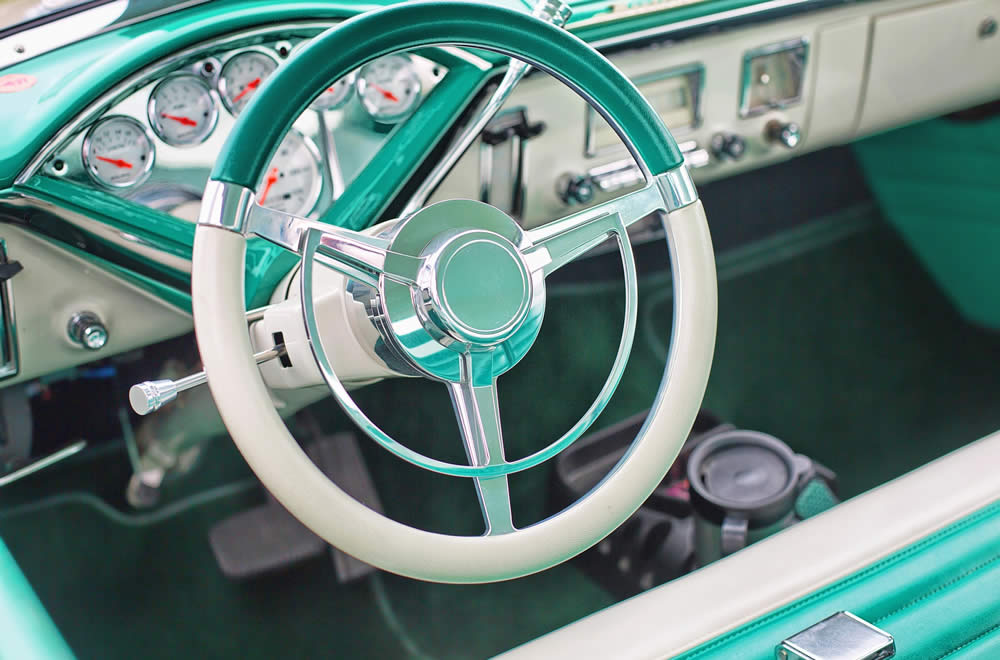

- Automotive and transport

- Medical and health technology

- Agricultural equipment and enclosures

- Marine-grade components

- Industrial and consumer packaging

With every project, our goal is to deliver precision, reliability, and value to South West supply chains.

Our Services: Complete Plastic Injection Moulding Solutions

We provide everything under one roof – streamlining your procurement and accelerating your go-to-market timeline.

Our toolroom engineers build precision CNC-machined moulds from aluminium or hardened steel. We handle both prototype and multi-cavity production tooling.

We review your CAD drawings or product concept to optimise geometry, wall thickness, draft angles and material selection for manufacturability and cost-effectiveness.

We run a fleet of modern moulding machines capable of producing lightweight plastic housings, high-strength functional parts, and cosmetic-finish consumer products. Materials include ABS, polypropylene, PA, PC, TPE, and filled compounds.

Need more than a single part?

We offer value-added services such as ultrasonic welding, drilling, printing, and part assembly - delivering your components ready for use.

From daily call-off orders to scheduled project deliveries, we offer flexible packaging and shipping to locations throughout the South West and the wider UK.

Why Work with Stephens Plastic?

1. Local Access, National Capability

As a UK-based plastic injection moulding supplier, we combine local service with national reach – serving manufacturers in Bristol, Exeter, Swindon, Gloucester, and beyond.

2. Flexible Batch Sizes

We support everything from low-volume custom parts to full-scale production. There are no strict minimum order quantities, giving you control and scalability.

3. ISO 9001:2015 Certified

Our quality control processes are rigorous, documented, and continually reviewed—offering full traceability and peace of mind.

4. Material Knowledge & Innovation

We help you select the right material for performance, compliance, and cost – offering expert input on recyclability, strength, heat resistance, and surface finish.

5. Technical Partnership

We don’t just mould parts – we help you solve problems. From product development support to production efficiency tips, our team works closely with yours at every stage.

Plastic Injection Moulding: How It Works

Plastic injection moulding is the process of forming plastic parts by injecting molten material into a custom-designed metal mould. Once cooled, the part is ejected, producing consistent shapes with minimal variance.

This process is ideal for:

- Complex geometries

- Tight tolerances

- Repeated production runs

- Minimal waste

- Fast cycle times

Whether you’re creating a simple housing or a multi-material assembly, injection moulding offers the best of speed, precision, and repeatability – especially when managed by an experienced UK supplier like Stephens Plastic.

FAQs – Plastic Injection Moulding South West

Yes. We work with businesses of all sizes and can accommodate trial runs or niche product batches without enforcing large MOQs.

Typically, mould tooling is completed in 3 - 5 weeks. We keep all toolmaking in-house to reduce turnaround time and ensure quality.

We work across medical, electronics, transport, marine, packaging, and more - customising our approach to each sector's requirements.

Absolutely. We’ll recommend the most suitable polymer based on strength, cost, finish, and environmental conditions.

Yes. We deliver to businesses in Bristol, Exeter, Swindon, Cheltenham, Plymouth, and the surrounding areas with fast turnaround and flexible call-off options.

Contact a Leading Plastic Injection Moulding Company for the South West

Whether you’re launching a new product or looking to improve your current supply chain,

Stephens Plastic Mouldings offers precision-moulded components you can depend on – backed by UK production, technical support, and ISO-certified processes.

Request a Quote today

Speak to a Specialist OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.