Plastic Injection Moulding Slough

Precision Plastic Injection Moulding for Slough’s Industrial Base

Stephens Plastic Mouldings is a UK plastic injection moulding company supporting businesses across Slough and the Thames Valley. We offer tailored, end-to-end injection moulding services to help manufacturers, engineers, and product innovators bring their designs to life with accuracy, speed, and cost-efficiency.

Where required, we can outline comparable projects and sector experience relevant to your application. Although many client engagements are subject to NDA, suitable case studies can be discussed confidentially.

We are ISO 9001:2015 certified and provide full control from tooling to production. Whether you’re launching a new product, scaling up production, or seeking a reliable UK-based supplier, we help you take control of your plastic part supply chain.

Serving Slough’s Thriving Business Landscape

As one of the most economically active towns in the South East, Slough hosts a wide range of sectors – including logistics, pharmaceuticals, electronics, and automotive. These industries depend on dependable suppliers who can deliver parts with speed, compliance, and quality assurance.

At Stephens Plastic, we support companies in and around Slough with plastic components tailored to their technical and commercial requirements. From single – use enclosures to precision electrical housings, our capabilities ensure performance and consistency every time.

Why Choose Stephens Plastic as Your Slough Injection Moulding Partner?

Avoid offshore delays with a local partner who delivers consistent results—on time and to spec.

Whether you're starting with a short run or managing regular high-output schedules, we scale around your demand.

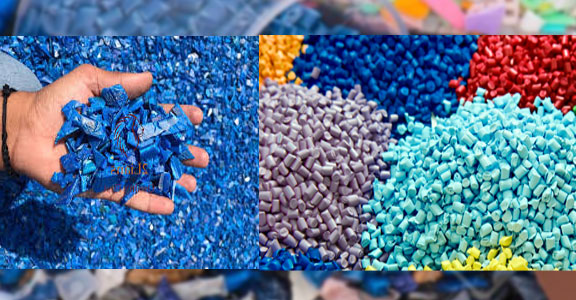

Choose from ABS, polycarbonate, PBT, polypropylene, nylon, elastomers, and more - including recyclable and flame-retardant options.

Quality is built into everything we do. Every batch is traceable, tested, and backed by documented assurance.

Get expert input, clear communication, and proactive solutions from our experienced team. We treat your project like it's our own.

Complete Injection Moulding Services for Slough Clients

We’re more than just a production facility – we’re a problem-solving partner. We’ll adapt our approach to your industry, timeline, and cost targets.

Our services include:

1. Design for Manufacture (DFM)

Review your design for mouldability and efficiency.

2. Tooling Development

In-house production of steel or aluminium mould tools with rapid turnaround.

3. Prototype & Sampling

Quick-turn pilot runs to test materials and form before committing to volume.

4. Full Production Runs

Low – to high-volume injection moulding using the latest automated machines.

5. Post-Mould Finishing

Ultrasonic welding, pad printing, overmoulding, trimming, and part assembly.

6. Custom Packing & Logistics

Secure shipment from our Midlands-based site to Slough and the wider South East.

What Can Injection Moulding Be Used For?

Plastic injection moulding is the ideal method for producing complex or high-volume plastic parts with a high degree of accuracy.

Using a machined mould, molten plastic is injected into a closed cavity under pressure, then cooled and ejected as a finished part.

This repeatable, high-speed process is used across industries in Slough for:

- Electronic enclosures and switch housings.

- Pharmaceutical and laboratory trays.

- Logistics packaging clips and handles.

- Consumer product casings and components.

- Automotive interior and under-bonnet parts.

Injection moulding offers predictable quality, low cost per part (at volume), and wide material choice – making it a scalable, sustainable solution.

FAQs

Yes - our engineers can assist with DFM advice and help optimise your design for the moulding process.

Absolutely. We welcome low-quantity orders and offer flexible manufacturing for pilot or niche batches.

Tooling generally takes 3 - 6 weeks. Once production begins, parts can often be shipped within 5 - 10 working days.

Yes. We can recommend and work with recycled, biodegradable, or low-impact polymers where suitable.

Yes - we offer fast, reliable delivery throughout Slough and the surrounding areas, with custom packaging on request.

Speak to Slough’s Trusted Plastic Injection Moulding Specialists

If you’re based in Slough and need a reliable plastic injection moulding supplier with UK production, ISO-certified processes, and a customer-first mindset,

We’re ready to help.

Serving Slough & South East | ISO 9001:2015 Certified | UK Tooling & Production.

Request your Quote OR

Speak to a Project Engineer OR Visit Website

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.