Plastic Injection Moulding Redditch

Engineered in the Midlands. Delivered with Confidence

Redditch has a proud history of manufacturing excellence—from precision-engineered components to global export products. Today, it’s a key part of the UK’s advanced engineering and packaging supply chains. At Stephens Plastic Mouldings, we’re proud to support Redditch-based manufacturers, product developers, and OEMs with flexible, full-service plastic injection moulding solutions.

Whether you need a prototype in weeks or a long-term production partner, we provide UK-made quality, fast lead times, and tailored technical support – with no minimum order quantity.

If case studies or regional references would support your decision-making, please contact our team. While NDAs often prevent public attribution, we can discuss relevant work across most sectors and locations in confidence.

Why Redditch Manufacturers Choose Us

Stephens Plastic Mouldings is more than just a component supplier – we’re a technical partner for manufacturers across Worcestershire and the West Midlands.

Here’s what sets us apart:

- UK-based production with no hidden delays or import complications.

- ISO 9001:2015 certified for full traceability and process control.

- No minimum order quantities – ideal for start-ups and specialist parts.

- End-to-end project management for simple, coordinated delivery.

- Personalised service from a Midlands team that understands your goals.

Our Injection Moulding Services

We handle everything under one roof – from concept through to packed, delivered parts – so you don’t need to manage multiple suppliers.

Got an idea, concept sketch, or CAD file? Our engineering team offers design for manufacture (DFM) input to ensure your part is optimised for injection moulding. We’ll guide geometry, tolerances, wall thickness, and material choice - reducing cost and ensuring reliability.

This early-stage collaboration prevents production issues and speeds up development - ideal for teams on tight timelines or limited tooling budgets.

We build all mould tools in-house - from prototype aluminium tools to high-volume multi-cavity steel tooling. This keeps your project moving and gives us full quality control.

You’ll benefit from:

- Shorter lead times (no third-party delays).

- Tool designs customised to your part and volumes.

- Consistent performance across every batch.

We may also offer trial tooling to validate your design before full production, lowering risk and upfront costs.

Before committing to high volumes, it’s often wise to test fit, function, and finish. We offer:

- Quick-turn prototype tooling.

- Short-run injection moulding.

- 3D-printed pre-mould evaluation parts (if appropriate).

Our prototyping support helps Redditch clients meet tight approval windows, refine early-stage concepts, and win stakeholder signoff - all with lower investment and faster turnaround.

This is what we do best - reliable, repeatable moulded plastic parts made to your exact specifications.

We cater to every stage of your product lifecycle:

- Short batches for pilots or niche markets.

- Medium volumes with scheduled deliveries.

- High-volume production into the hundreds of thousands.

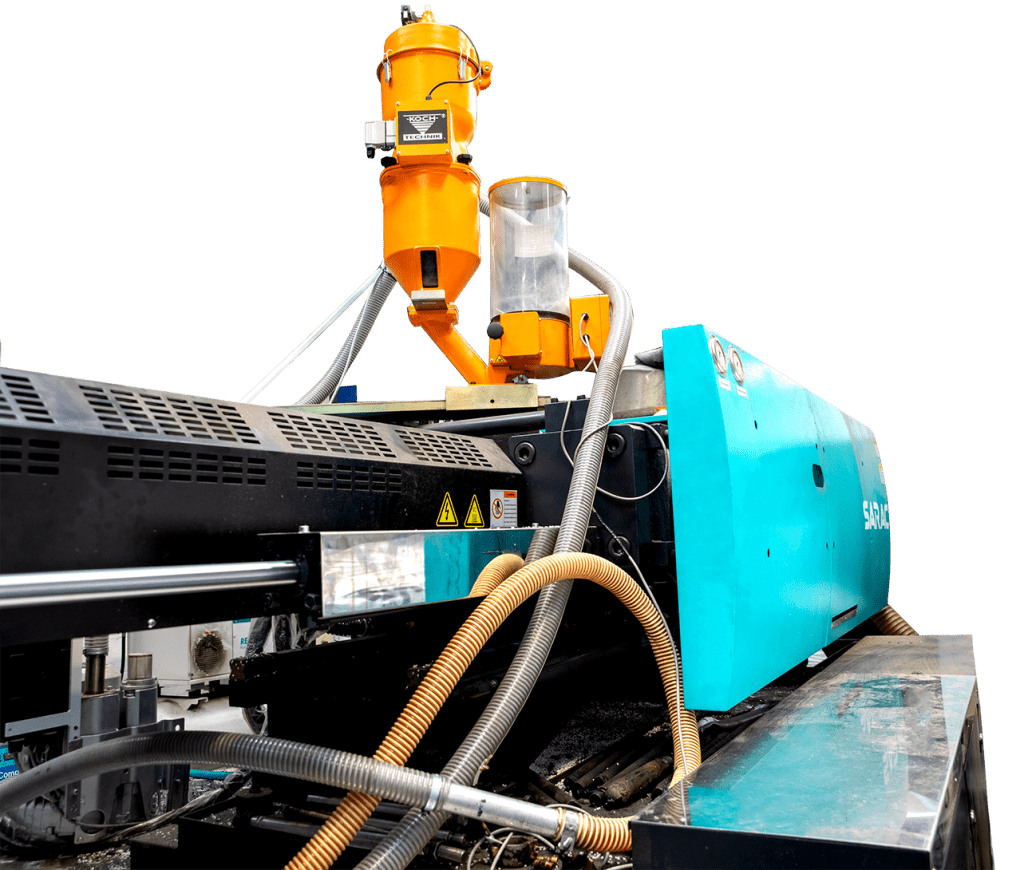

Our diverse fleet of modern moulding machines handles everything from small precision parts to larger, structural components - with clamp tonnages suited to a wide range of applications. We monitor every cycle using automated controls and ensure each batch meets your standards.

Need more than just a plastic part? We provide full post-mould processing, including:

- Machining or drilling.

- Ultrasonic welding.

- Pad printing and painting.

- Component assembly (e.g. inserts, seals, electronics).

We deliver turnkey plastic assemblies, ensuring that every part looks and performs exactly as intended - while reducing your internal handling time and assembly costs.

Once your parts are moulded and finished, we handle packaging and delivery too. Stephens Plastic offers:

- Protective packaging for delicate components.

- Labelling and kitting per your requirements.

- Call-off or scheduled delivery plans.

- National and international shipping options.

With our facility located in the heart of the UK, we serve Redditch with fast, reliable shipping and responsive service - keeping your production line running smoothly.

Supporting Redditch’s Diverse Industrial Base

We work with companies across Redditch’s leading sectors, offering plastic moulded parts tailored to their exact needs.

1. FMCG & Packaging

We produce custom closures, inserts, and tamper-proof trays for food, drink, and cosmetics packaging – using food-grade polymers and smooth, branded finishes.

2. Engineering & Subcontract Manufacturing

Whether it’s a sensor housing, functional bracket, or machine component – we offer durable, high-spec plastics to meet industrial tolerances.

3. Scientific & Medical Devices

For Redditch’s growing medtech and diagnostics industry, we deliver enclosures, disposable trays, and test housings in certified materials.

4. Consumer Products & Assembly

We support local product designers and manufacturers with flexible prototyping and scalable production runs – helping new ideas come to life with precision.

Material Selection & Guidance

We offer a full portfolio of injection-moulding-ready thermoplastics:

- ABS, Nylon, Polycarbonate, Polypropylene.

- Flame-retardant and UV-resistant materials.

- Flexible materials (TPU, TPE).

- Medical and food-approved resins.

- Bioplastics and recycled content options.

Our team will help you select the ideal material based on your functional, environmental, and regulatory requirements.

FAQs

Yes. Whether you need 50, 500, or 50,000 parts - we're happy to support your scale. We don’t enforce minimum orders.

Absolutely. We often work with early-stage designs and can reverse-engineer from physical samples to produce production-ready CAD files and tools.

Tooling typically takes 3 - 6 weeks. Prototypes or sample tools may be completed even sooner depending on complexity.

Yes. Stephens Plastic Mouldings operates under ISO 9001:2015, ensuring quality control, process repeatability, and full part traceability.

Yes. We ship daily to Redditch and across the Midlands. Special delivery arrangements or call-off schedules can also be arranged.

Start Your Project with Stephens Plastic

Whether you’re improving an existing product, launching something new, OR

Streamlining your component supply-Stephens Plastic Mouldings is here to support your Redditch business.

– No Minimum Order | UK-Based Manufacturing | ISO 9001 Certified

– Fast Turnaround | In-House Tooling | Collaborative Engineering

Contact us

For a no-obligation quote or design consultation today.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.