Why Injection Moulding Techniques Matter in 2026

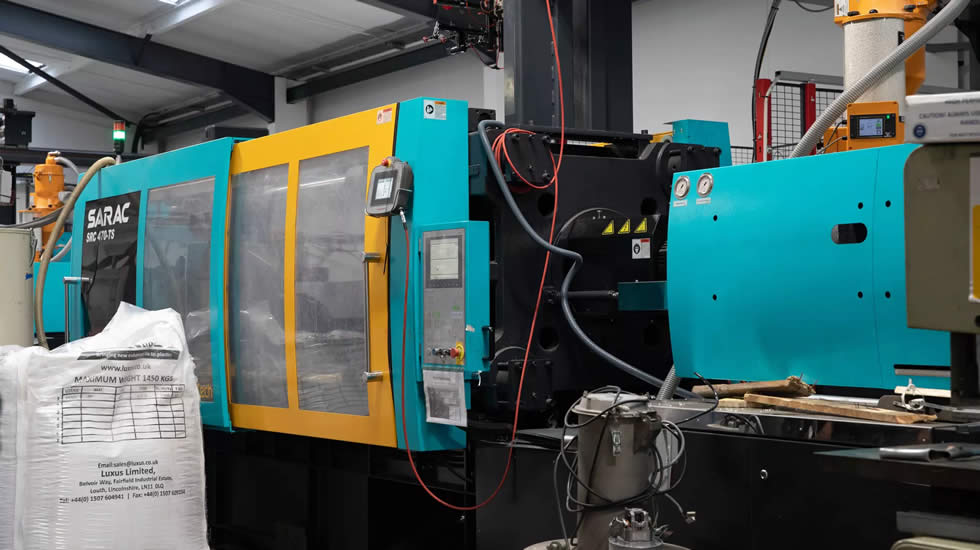

Plastic injection moulding remains one of the most important manufacturing processes globally—but success is no longer defined by machinery alone. In 2026, performance depends on how injection moulding techniques are applied, controlled and optimised across the entire production lifecycle.

At Stephens Plastic Mouldings, injection moulding is treated as a system, not a single process step. Design, tooling, material selection, moulding parameters and quality control are all engineered to work together to deliver consistent quality, predictable costs and scalable production.

This guide explains the core injection moulding techniques used in modern manufacturing and what they mean in practical, commercial terms.

1. Design for Injection Moulding: Where Outcomes Are Decided

Engineering the Part Before the Tool Exists

The most critical injection moulding technique happens before production begins: design for manufacture (DFM).

At Stephens Plastic Mouldings, DFM focuses on:

- Optimised wall thickness and geometry

- Correct draft angles for reliable ejection

- Controlled tolerances aligned with function

- Reduced complexity to lower tooling risk

Good design reduces scrap, shortens cycle times and prevents expensive tooling revisions later in the project.

2. Tooling Techniques: Precision That Enables Repeatability

Tooling as a Long-Term Performance Asset

Injection mould tooling determines whether a process is stable or variable.

Our tooling techniques prioritise:

- Accurate cavity geometry

- Efficient cooling channel design

- Balanced flow and fill behaviour

- Durability across production volumes

Well-engineered tooling supports repeatable quality, predictable lead times and strong return on investment.

3. Material Selection Techniques: Matching Polymer to Performance

Choosing the Right Plastic, Not the Cheapest

Material selection is a technical and commercial decision.

Injection moulding material techniques involve evaluating:

- Mechanical and environmental performance

- Dimensional stability

- Processing behaviour and cycle efficiency

- Regulatory or sector-specific requirements

Selecting the correct polymer prevents downstream issues such as warpage, premature failure or inconsistent batches.

4. The Injection Moulding Process: Controlled Production in Practice

From Melt to Mould

The core injection moulding technique involves:

- Heating plastic granules to a molten state

- Injecting material into the mould under controlled pressure

- Maintaining precise temperature and injection parameters

This stage demands tight process control to ensure consistent part quality across every cycle.

5. Cooling and Ejection: Protecting Part Integrity

Where Many Defects Are Prevented

Cooling is not simply waiting for plastic to solidify. It is a controlled phase that influences:

- Dimensional accuracy

- Internal stress levels

- Surface finish quality

Correct cooling techniques reduce warping, sink marks and long-term part instability.

6. Post-Processing Techniques: Refinement, Not Correction

Finishing That Adds Value

Post-processing may include:

- Trimming or deflashing

- Surface finishing

- Assembly or secondary operations

When injection moulding techniques are applied correctly earlier in the process, post-processing enhances functionality and appearance rather than compensating for defects.

7. Quality Control Techniques: Consistency at Scale

Quality Embedded Throughout Production

At Stephens Plastic Mouldings, quality control is integrated into every stage, supported by ISO 9001 quality management systems.

Quality techniques include:

- In-process monitoring

- Dimensional inspection

- Material traceability

- Documented process control

This ensures consistency across production runs, not just compliance at final inspection.

Advanced Injection Moulding Techniques Used in Modern Manufacturing

Beyond standard moulding, advanced techniques may include:

- Overmoulding for multi-material components

- Insert moulding for integrated assemblies

- Low-volume and bridge moulding strategies

- Automation-supported moulding for repeatability

These techniques allow manufacturers to balance complexity, performance and cost without compromising reliability.

Why Injection Moulding Techniques Matter to Buyers

For engineers, procurement teams and product managers, injection moulding techniques directly influence:

- Unit cost and cost stability

- Product quality and durability

- Lead time reliability

- Scalability and future flexibility

Understanding how techniques are applied is essential when selecting a manufacturing partner.

FAQs

1. What are the most important injection moulding techniques?

Design for manufacture, precision tooling, controlled moulding parameters, effective cooling and embedded quality control are the most critical techniques.

2. How do injection moulding techniques affect product quality?

Well-applied techniques reduce variability, improve dimensional accuracy and ensure consistent performance across production runs.

3. Are advanced injection moulding techniques suitable for low-volume production?

Yes. Advanced techniques are particularly effective for low-volume and specialist production where precision and repeatability are essential.

4. Why choose a UK manufacturer for injection moulding?

UK manufacturers offer better communication, tighter quality control, shorter lead times and reduced supply chain risk.

5. Can Stephens Plastic Mouldings support complex injection moulding projects?

Yes. We specialise in precision and technical injection moulding, supporting projects from early design through scalable production.

Final Insight: Injection Moulding Is a System, Not a Single Step

Injection moulding success is determined by how techniques are applied together, not in isolation.

When design, tooling, materials, processing and quality control are aligned, manufacturers achieve:

- Predictable quality

- Controlled costs

- Scalable production

- Long-term manufacturing confidence

At Stephens Plastic Mouldings, injection moulding techniques are applied as a cohesive system to deliver reliable outcomes.

Call to Action

If you’re evaluating injection moulding techniques for a current or upcoming project and want a UK-based manufacturing partner focused on quality, efficiency and long-term value, our team is ready to help.

Contact Stephens Plastic Mouldings to discuss your requirements or request a tailored quotation.