Plastic Injection Moulding Plymouth

Precision Moulding Solutions for Plymouth’s Industrial Economy

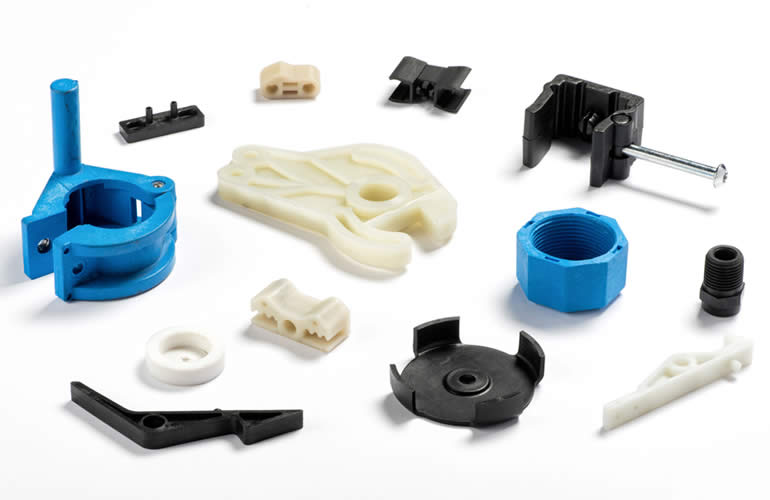

Stephens Plastic Mouldings proudly serves Plymouth and the wider South West with UK-manufactured plastic injection moulding tailored to demanding commercial needs. From shipbuilding components to marine-grade enclosures and medical device casings, our full-service operation supports the region’s expanding industrial sectors.

We are an ISO 9001-certified plastic injection moulding company delivering consistent, on-spec plastic components to manufacturers, OEMs, and innovators across Plymouth. Our team works closely with your engineers from day one – ensuring cost-effective, technically sound parts with short lead times and no strict minimum orders.

Supporting Marine, Defence, and Tech Sectors in Plymouth

Plymouth is a recognised hub for marine technology, defence systems, and advanced manufacturing. At Stephens Plastic, we understand the unique challenges and material requirements these industries face.

Our specialists recommend fit-for-purpose thermoplastics and deliver precise tooling to match your operational needs.

Whether you’re producing low-run, safety-critical parts or need mass production with tight tolerances, our systems ensure delivery with speed, reliability, and process control.

End-to-End Plastic Injection Moulding Services in Plymouth

Our capabilities go beyond production. Stephens Plastic is a full-service UK injection moulding partner offering:

We create custom moulds in-house using CNC precision machining. Our engineers advise on part design, geometry, and material selection to optimise cost, performance, and durability.

Our factory houses a range of modern moulding presses to accommodate everything from micro-parts to large industrial housings. We process ABS, polypropylene, nylon, PC, and more.

Need to validate a design or get to market fast? We produce prototype moulds and trial batches quickly, so you can test fit, form, and function without high upfront costs.

We provide part finishing, sub-assembly, component insertion, and printing - delivering ready-to-use products directly to your site.

From our central location, we deliver throughout the South West, ensuring fast turnaround times and reliable delivery schedules.

Why Choose Stephens Plastic in Plymouth?

1. ISO 9001-Certified Manufacturing

Our operations meet rigorous quality standards with full traceability and repeatable process controls.

2. Flexible Production Volumes

We support low – and high-volume moulding projects. There are no minimum order quantities, allowing you to scale as needed.

3. In-House Tooling Expertise

By controlling the tooling phase, we cut lead times and ensure every part meets specification from the first shot.

4. Strategic UK Location

Serving Plymouth means rapid transport, face-to-face collaboration if required, and an understanding of local industries – from defence to marine systems.

5. Personalised Service

We assign a single point of contact for your project. Our engineers and project managers work collaboratively to ensure you receive transparent updates and technical support throughout.

The Injection Moulding Process: Built for Quality, Scale, and Consistency

Plastic injection moulding is one of the most efficient ways to create complex plastic components at scale. The process begins with a custom-designed steel or aluminium tool, into which molten thermoplastic is injected under pressure. Once cooled, the part is ejected and the cycle repeats.

This repeatable process makes injection moulding ideal for producing large volumes of identical parts with tight tolerances and consistent finishes. It’s commonly used in Plymouth’s marine, electronics, medical, and industrial sectors for components that must be durable, accurate, and cost-effective.

FAQs – Plastic Injection Moulding Plymouth

We work with a wide range of thermoplastics including ABS, PP, nylon, PC, PEEK, and marine-grade engineering materials based on your application.

Yes. We offer prototype injection moulding with quick-turn tooling, as well as 3D printing for concept validation.

We do. Secondary operations such as ultrasonic welding, insert installation, pad printing, and assembly are available in-house.

Tooling takes 3 - 5 weeks on average. Production and delivery are typically within 2 - 3 weeks after tooling approval.

We work with businesses of all sizes. Many of our clients start small with low volumes and grow with us over time.

Work With a Reliable Injection Moulding Company in Plymouth

Stephens Plastic Mouldings is more than just a supplier – we’re a long-term partner for plastic component success. From concept to completion, we help manufacturers in Plymouth develop better parts, speed up production, and lower cost per unit.

Request a Free Quote

Consultation today OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.