Plastic Injection Moulding North East

Trusted Plastic Moulding Solutions Across the North East

Searching for a plastic injection moulding company in the North East that delivers on quality, speed, and service?

Stephens Plastic Mouldings is your go-to partner.

If you would like to review relevant case studies, please feel free to contact us. While many client relationships are protected by confidentiality agreements, we are able to discuss applicable case studies across a wide range of regions and industry sectors in confidence.

We’ve been manufacturing custom plastic components for over 20 years, working closely with clients across Newcastle, Sunderland, Durham, Middlesbrough, Hartlepool, and beyond.

Whether you’re a startup looking for prototype runs or an established manufacturer scaling production, we offer tailored solutions that reduce lead times, improve part quality, and keep your operations moving.

Why Stephens Plastic Mouldings?

We bring more than two decades of proven experience in producing complex, tight-tolerance plastic parts. Our specialists have supported clients in automotive, medical, packaging, electronics, and industrial sectors - delivering parts that perform under pressure.

Our work is guided by rigorous ISO 9001 standards. Every stage - from material selection to final batch inspection - is monitored for precision and consistency. You can expect reliable quality across every part, every time.

We handle everything in-house - from design consultation and tooling to moulding, assembly, and packaging. Whether you need full-service support or short-run production from your own tooling, we’ll tailor our involvement to suit your workflow.

Whether you need 20 parts or 200,000, we scale production to match your volume. Our lean systems allow us to pivot quickly and efficiently, giving you the flexibility to test products, ramp up, or respond to spikes in demand.

Our equipment includes automated injection moulding machines that produce high-precision components with tight cycle times. Combined with our material expertise, we're ready to handle complex geometries and advanced polymer requirements.

We treat your business like a partner, not a transaction. You'll have a dedicated point of contact, regular progress updates, and technical advice throughout your project lifecycle. Your goals become our goals.

With facilities strategically positioned to serve the North East, we understand the local supply chain, workforce, and industries. That means you benefit from reduced transport costs, fast communication, and responsive customer service - while still accessing national reach.

Industries We Support in the North East

- Automotive (Sunderland, Washington): Durable trim components, under-hood parts, clips, and connectors built to OEM specs.

- Medical & Life Sciences (Newcastle): Biocompatible plastic casings, medical-grade housings, and precision labware.

- Electronics & Controls (Middlesbrough): Enclosures, brackets, switchgear casings, and cable management solutions.

- Industrial & Energy (Teesside): Weather-resistant utility parts, smart metering housings, and structural inserts.

- Consumer & Packaging (Gateshead): Branded packaging, caps and closures, functional plastic retail components.

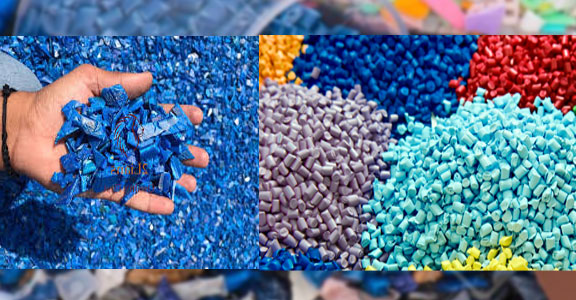

Our Injection Moulding Process – Explained

1. Design & Tooling

We work with you to develop or optimise a CAD model that’s suitable for injection moulding. Our engineers advise on wall thickness, draft angles, and material selection for optimal performance and cost efficiency.

2. Tooling Manufacture

We create high-precision steel or aluminium moulds tailored to your design, with options for soft tooling, prototype tools, or long-life production moulds.

3. Moulding & Quality Control

Molten thermoplastic is injected into the mould under pressure. Once cooled and solidified, each part is ejected, checked, and batch-verified for dimensional accuracy, fit, and finish.

4. Finishing, Assembly & Delivery

We offer secondary operations such as trimming, ultrasonic welding, and kitting, as well as custom packaging. Your parts arrive ready to use or assemble.

Common Applications

Our injection moulded parts are used across:

- Automotive clips, housings, and bezels.

- Medical device shells and connectors.

- Electrical enclosures and light fittings.

- Food packaging, trays, and containers.

- Warehouse bins and supply chain handling tools.

- Agriculture and irrigation parts.

- Retail product casings and display components.

FAQs

Yes! Our team provides CAD design assistance and offers 3D printing or low-volume moulding for prototyping. We ensure your design is manufacturable before tooling investment.

We work with ABS, polypropylene, polycarbonate, polyethylene, nylon, and glass-filled polymers. We also offer FDA-compliant, flame-retardant, and medical-grade options.

New tooling projects typically take 2 - 6 weeks for tooling and samples. Repeat orders or existing tools can ship in days. We prioritise urgent requests where possible.

Absolutely. We accommodate one-off prototypes, pilot runs, and full-scale production with no minimum order constraints.

No - we ship nationwide. But our location means clients in the North East benefit from faster logistics, easier communication, and regional insight.

Start Your Project With Us

Whether you’re launching a new product or need support with an existing part, we’re here to help.

Get in touch today to request a quote, send your drawings, or schedule a consultation.

Contact Stephens Plastic Mouldings

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.