Plastic Injection Moulding Liverpool

Advanced Injection Moulding Solutions for Liverpool Manufacturers

Stephens Plastic Mouldings provides high-precision plastic injection moulding services in Liverpool, supporting the region’s dynamic manufacturing, packaging, and medical sectors with cost-effective, scalable solutions. Whether you need high-volume production or a specialist low-run prototype, our UK-based team delivers parts with reliability, speed, and exceptional accuracy.

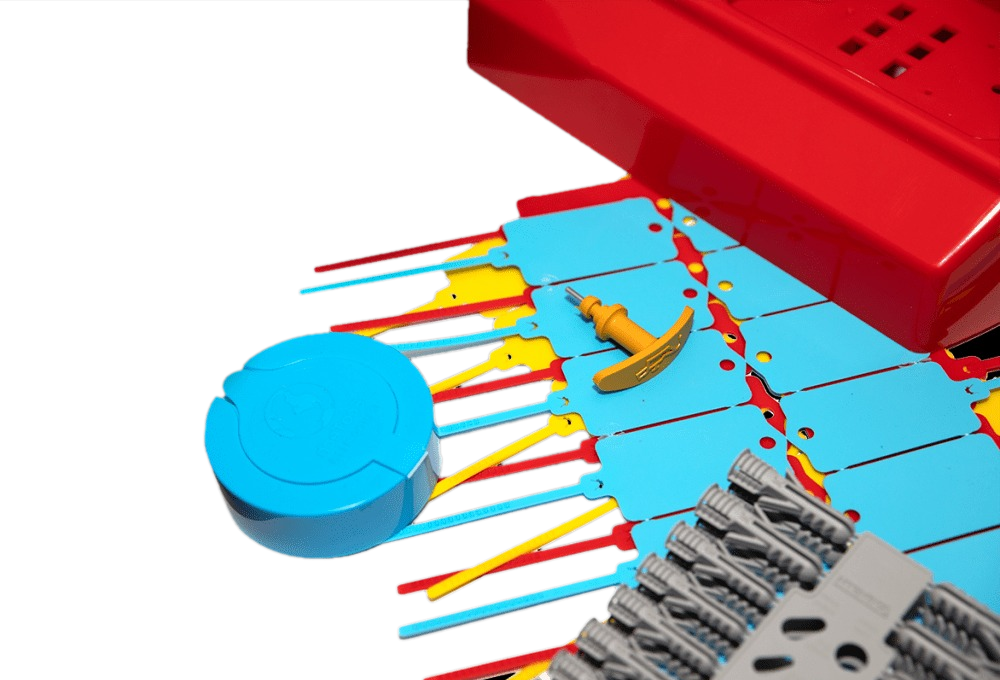

Injection moulding is one of the most versatile methods of plastic part manufacturing – used to produce a vast range of products from bottle caps and electronics housings to vehicle components and healthcare enclosures. It combines design freedom with tight tolerances, making it ideal for both industrial and consumer applications.

Our ISO 9001-certified team works with Liverpool’s manufacturers to bring ideas to life-from concept and tooling to delivery. We specialise in reducing lead times, minimising risk, and improving part consistency for businesses that demand results.

If you need reassurance through real-world examples, we can provide relevant case studies and references. Although client confidentiality often prevents public disclosure, we regularly discuss proven results across multiple sectors and locations in confidence.

Why Liverpool Businesses Choose Stephens Plastic

Liverpool is a port city that thrives on commerce, innovation, and infrastructure – and our injection moulding service reflects the same values. With in-house tooling, flexible production volumes, and deep technical expertise, we’re a responsive and transparent partner for local manufacturing operations.

Your Local Advantage:

- Full UK-based service: Design, tooling, moulding, and logistics.

- Zero minimum order quantities – ideal for startups or R&D teams.

- Material selection and compliance advice for regulated industries.

- Rapid tooling for early-stage iterations or bridge production.

- Real-time communication with dedicated account managers.

- Fast delivery across Liverpool and the wider North West.

We’re trusted by manufacturers in Merseyside to deliver plastic parts that meet performance, regulatory, and aesthetic standards – without compromise.

The Injection Moulding Process: How It Works

Injection moulding is a cyclical, highly repeatable process used to create detailed plastic components with tight tolerances.

1. Design & Tooling

Each project starts with a custom-designed mould, CNC-machined in aluminium or steel to the negative shape of the required part.

2. Material Injection

Thermoplastic pellets (e.g. polypropylene, ABS, nylon) are heated until molten, then injected into the mould under high pressure.

3. Cooling & Ejection

The plastic solidifies in the mould, capturing fine features and dimensions. The part is then ejected and the cycle begins again.

This process can produce thousands of identical components per day with minimal variation.

The result:

consistent, high-quality parts ideal for industries that demand precision and dependability.

Supporting Liverpool’s Leading Sectors

Our injection moulding capabilities align with key industries across Liverpool and Merseyside:

We mould parts for automation systems, enclosures, fasteners, and safety housings used in factories and production lines.

We support regional suppliers of diagnostic devices, storage systems, and consumer medical products with clean, compliant plastic components.

From caps and closures to custom product trays and containers, our solutions help Liverpool's fast-moving goods and retail suppliers keep products moving.

We support growth-focused companies in Liverpool's tech and startup scene with prototyping and low-volume production tailored to budget and scale.

Our End-to-End Moulding Services

From CAD to component, Stephens Plastic provides everything under one roof – reducing costs, speeding up timelines, and simplifying procurement.

1. Design for Manufacture

We help improve your design for better mould flow, reduced defects, and lower production costs.

2. Toolmaking

Our in-house tooling team builds prototype and production-grade moulds, allowing tighter control over timeframes and tool quality.

3. Prototyping

Test and validate your part design with low-volume samples before committing to full production.

4. Injection Moulding

We mould parts with advanced machines ranging in clamp force and shot size – suitable for both small technical items and larger enclosures.

5. Secondary Operations

We offer post-mould services such as drilling, welding, branding, assembly, and surface finishing for a production-ready outcome.

6. Delivery & Logistics

Strategically located in the West Midlands, we ensure timely delivery to Liverpool and all areas of Merseyside.

FAQs – Plastic Injection Moulding in Liverpool

Yes. Our UK-based toolroom designs and builds all tools to ensure fit, longevity, and rapid iterations.

We accept all major CAD formats and can support you with DFM and technical validation.

Yes. We use certified resins that meet FDA and ISO standards where required, with full traceability.

Depending on volume and tool status, lead times can range from 2 - 6 weeks. We regularly deliver to clients in Liverpool within 24 - 48 hours of production.

Yes - we work with eco-conscious brands to source regrind and biodegradable materials that meet performance and sustainability goals.

Talk to Liverpool’s Trusted Injection Moulding Partner

At Stephens Plastic Mouldings, we help Merseyside manufacturers move from concept to production with confidence.

With local service, engineering insight, and complete in-house capabilities, we’re the injection moulding supplier you can rely on – whether you need 100 parts or 100,000.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.