Plastic Injection Moulding Halesowen

Moulded Solutions for West Midlands Industry

Halesowen’s manufacturing story is built on craft, precision, and adaptability. From metal fabrication and components to product innovation and subcontract supply, the town plays a vital role in the West Midlands’ engineering ecosystem.

At Stephens Plastic Mouldings, we support Halesowen-based companies with reliable, scalable plastic injection moulding–produced in the UK, engineered for performance, and delivered on time. Whether you’re making bespoke industrial parts, commercial products, or prototyping something new, we’re your technical partner for every step of the journey.

Our experience spans a broad range of regions and industry sectors. Although client confidentiality restricts public citation in many cases, we are able to discuss relevant case studies and comparable projects on a confidential basis.

Why Manufacturers in Halesowen Choose Us

Located less than 15 miles from Halesowen, our production facility combines advanced injection moulding with local service.

Our team works closely with West Midlands SMEs, startups, and supply chains to deliver quality parts – without the delays of international sourcing or the limits of generic moulders.

Here’s how we help:

- Flexible batch sizes with no minimum order quantity.

- Free tooling consultations and prototyping options.

- ISO 9001-certified UK manufacturing.

- Full in-house service – from design to assembly.

- Delivery and support tailored for the Black Country region.

Our Services: From Tooling to Turnaround

| Service | Your Advantage |

|---|---|

| Design & Engineering | We assess your part design for performance, cost, and manufacturability – ensuring success before tooling. |

| Toolroom Manufacturing | Aluminium and steel moulds built in-house for short runs or continuous production. |

| Injection Moulding Production | Precision parts delivered fast – 1 to 100,000+ units. No rigid volumes. |

| Specialist Processes | Insert moulding, overmoulding, and multi-cavity tooling for complex or combined parts. |

| Post-Mould Handling | Ultrasonic welding, assembly, finishing, packaging – your parts, fully ready to go. |

| Materials Expertise | Medical, food-safe, high-impact, flame-retardant, UV-stable, and eco-grade plastics available. |

Who We Serve in Halesowen

Halesowen’s businesses are diverse, but many share a need for reliable, flexible production partners.

We’ve built long-term relationships with companies that value:

- Speed to market.

- Quality without compromise.

- Support for both prototyping and production.

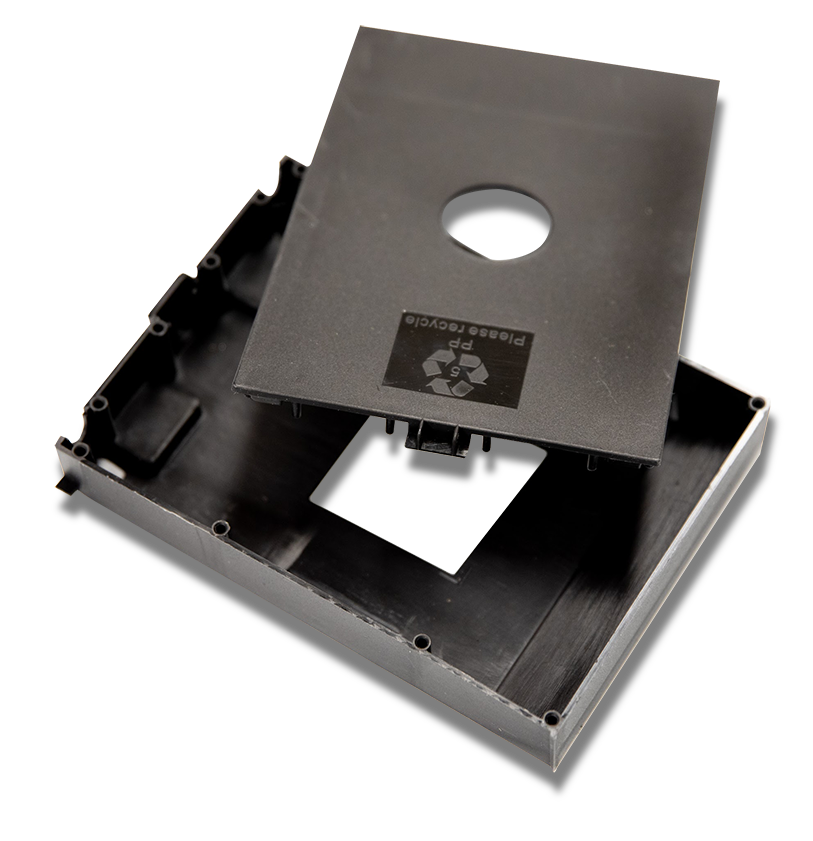

We support local metal and mechanical shops with complementary plastic parts - housings, brackets, knobs, and structural mouldings.

Plastic trays, closures, clips, and dispensers for brands producing and packing goods in and around the Halesowen area.

Enclosures, guards, and control panels for workshop and light industrial equipment manufacturers.

Custom plastic parts for gauges, kits, diagnostics, and other lab / testing environments where consistency is key.

Materials That Fit the Purpose

We work with a wide range of plastics, each selected for your product’s specific performance and cost requirements.

- General-use polymers: Polypropylene (PP), Polystyrene (PS), Polyethylene (HDPE/LDPE).

- Engineering materials: ABS, Polycarbonate (PC), Nylon (PA6/PA66).

- Specialty grades: Flame-retardant, UV-stable, impact-modified, anti-static (ESD-safe).

- Eco-conscious choices: Regrind plastics, recycled materials, and bioplastics.

- Certified plastics: Food-grade and medical-compliant polymers with traceability.

We’ll help you weigh performance, certification, and sustainability at every step.

FAQs

Absolutely. We work with businesses of all sizes - from single-product startups to established OEMs. Our no-MOQ approach makes injection moulding accessible for everyone.

Yes. We regularly assist in redesigning legacy components or heavy parts to benefit from weight reduction, corrosion resistance, or lower production cost.

We offer expedited tooling and production schedules for critical projects. We’ll work with you to meet urgent launch dates or prototype demos.

Yes - we’re a short drive from Halesowen. On-site visits, tooling reviews, or production meetings are welcomed. We’re local and approachable.

Yes. We work with clients to reduce waste, use recycled plastics, and explore biodegradable materials that meet performance standards.

Let’s Build Something Better, Together

Looking for a plastic injection moulding company near Halesowen that delivers quality, flexibility, and straight-talking support?

Stephens Plastic Mouldings is ready to help – from a single prototype to tens of thousands of precision-moulded parts.

– Local Support | In-House Toolroom | ISO 9001 Certified

– Low Volumes Welcome | Sustainable Options Available

Contact our Team

Today to discuss your next project.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.