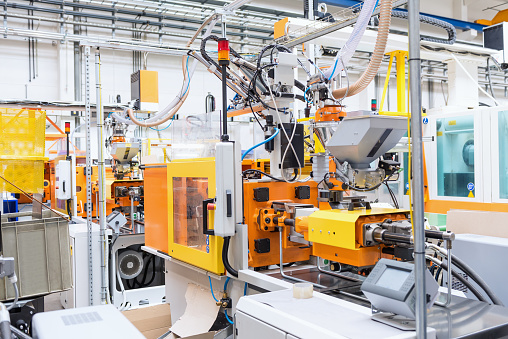

How Does Plastic Injection Moulding Enhance Vehicles?

22 February 2025

Plastic injection moulding is one of the most advanced manufacturing techniques for companies in the automotive industry. Comparable to agriculture and rail industries, it’s becoming increasingly sought after for its durable and aesthetic properties. Due to the nature of a vehicle, it requires parts that support its longevity and preserve its appearance, as well as […]