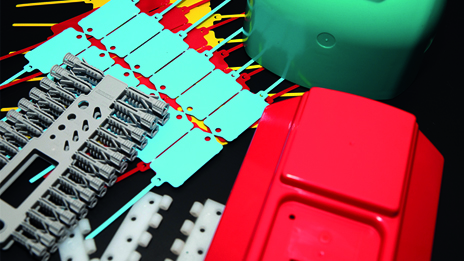

Thermoplastics vs Thermosets: Which Material is Best for Your Injection Moulded Component?

15 November 2025

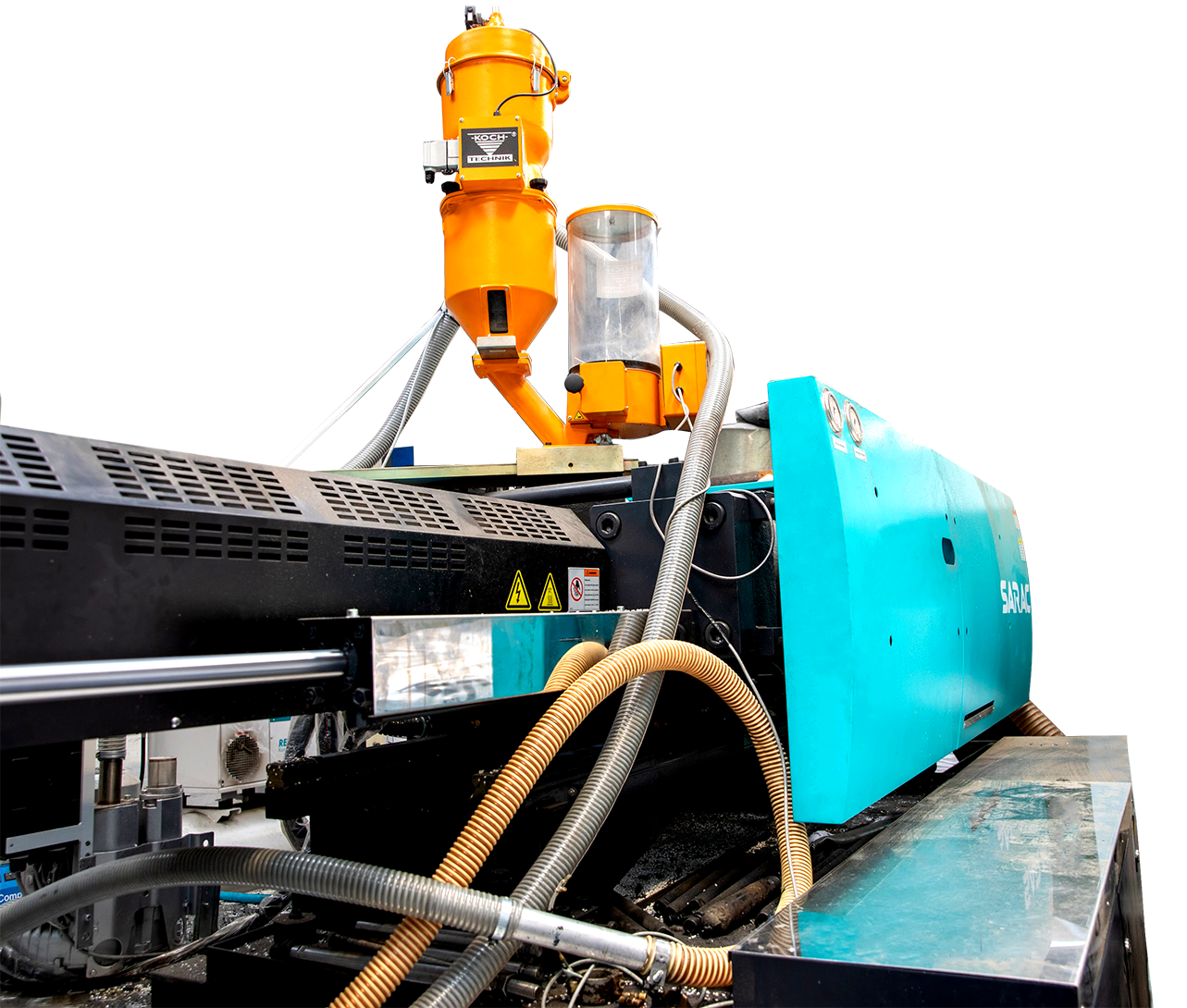

Choosing the right plastic for your injection moulded part goes beyond strength and aesthetics. Whether you’re in automotive, medical, aerospace, or industrial manufacturing, the distinction between thermoplastics and thermosets could be the difference between success and failure. At Stephens Plastic Mouldings, we help clients across the UK choose the right polymer based on the part’s […]