Plastic Injection Moulding Croydon

Supporting Croydon’s Industry With Precision Plastic Injection Moulding

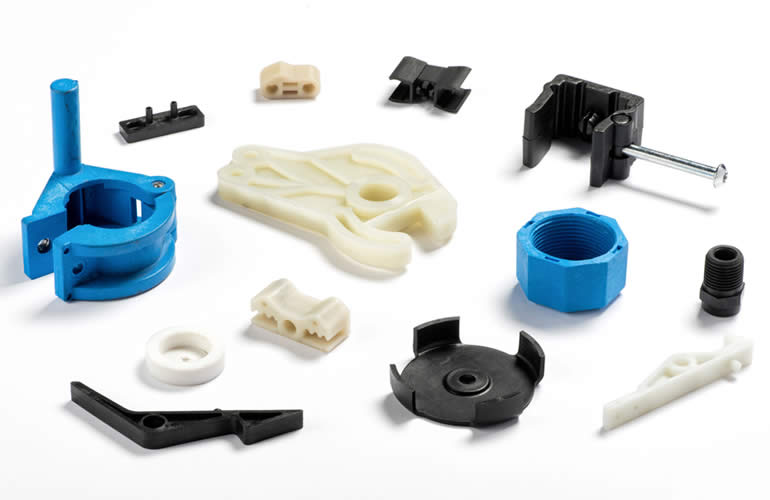

Stephens Plastic Mouldings delivers high-performance, UK-made plastic components to manufacturers and businesses across Croydon and South London. We specialise in plastic injection moulding for precision parts, offering full support from design to delivery.

With decades of experience, an in-house toolroom, and ISO 9001:2015 certification, we help local supply chains stay efficient, scalable, and fully compliant.

Whether you’re developing a new product or need a long-term production partner, our UK-based team will manufacture your plastic components to exact specifications – on time, every time.

A Manufacturing Partner for Croydon’s Diverse Economy

Croydon is home to growing clusters in engineering, tech, healthcare, and logistics. These sectors require reliable plastic part suppliers who can move quickly, ensure dimensional accuracy, and offer scalable production.

We support Croydon-based companies with parts for a variety of applications:

- Custom electrical housings.

- Structural packaging components.

- Medical plastic trays and accessories.

- Consumer enclosures and branded plastic parts.

- Logistics clips, bins, or stacking inserts.

Every part is produced with precision equipment, managed through ISO 9001 processes, and built to meet your performance and delivery goals.

Why Stephens Plastic?

All tooling and production is handled here in the UK - giving you shorter lead times and consistent oversight.

We support everything from low-volume prototyping to large-scale manufacturing - no minimum order quantities required.

We work with standard and high-performance polymers, helping you select the right material for function, compliance, and sustainability.

From initial consultation to final delivery, we work closely with your team to align with timelines, targets, and technical needs.

We are ISO 9001:2015 certified, meaning every part is fully traceable with documented checks throughout the process.

Our Plastic Injection Moulding Services for Croydon

We offer a complete, vertically integrated service model to support every stage of your project:

1. Design Review & DFM Advice

We help you prepare your part design for production with Design for Manufacture (DFM) input to reduce cost, improve durability, and ensure manufacturability.

2. Tooling Manufacture

Our in-house toolroom produces steel or aluminium mould tools, allowing us to control lead times, cost, and quality – without relying on third-party suppliers.

3. Prototyping & Pre-Production

Validate your design with prototype tooling and short sampling runs. We can also provide 3D-printed alternatives for early-stage testing.

4. Scalable Moulding Production

We manufacture small to large volumes of plastic parts using a variety of thermoplastics (ABS, PP, PA, PC, TPE, etc.), tailored to your needs.

5. Post-Mould Processing

Need assembly, trimming, welding, or printing?

We offer secondary services to finish or combine moulded parts to your specifications.

6. Logistics & Call-Off Orders

We ship directly to your Croydon facility or fulfil call-off agreements to ensure timely delivery and controlled stock levels.

Understanding Plastic Injection Moulding

Plastic injection moulding is one of the most widely used methods for producing high-quality plastic components. The process involves heating plastic pellets until molten, injecting them into a custom-machined mould cavity, and cooling them into a final shape.

This repeatable technique is ideal for:

- Tight-tolerance parts.

- Repetitive, high-volume production.

- Smooth finishes and defined details.

- Minimal waste and material optimisation.

Croydon-based companies benefit from reduced production cost per unit and faster time-to-market with this reliable method.

FAQs

Yes. We review CAD files and offer DFM advice to prevent design issues and streamline production.

Tooling generally takes 3-5 weeks. Parts can often be delivered within 1-2 weeks after tooling approval, depending on quantity and complexity.

Yes, we welcome small batch runs and pilot production without enforcing minimum order quantities.

We work across medical, logistics, packaging, consumer products, lighting, and more.

Yes. We support recycled and eco-friendly material options where compatible with the design and application.

Get Started With a Trusted Plastic Injection Moulding Company in Croydon

Whether you’re sourcing a new supplier OR

Scaling your product line, Stephens Plastic Mouldings provides everything you need to manufacture plastic parts with speed, accuracy, and confidence.

Serving Croydon, South London & Beyond | ISO Certified | UK-Based Manufacturing.

Request a tailored Quote OR

Speak with our Technical team OR Visit Website

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.