Plastic Injection Moulding Luton

A Plastic Injection Moulding Supplier You Can Rely On

Stephens Plastic Mouldings is a UK leader in delivering custom plastic injection moulding solutions, proudly supporting manufacturers, OEMs, and product developers in Luton and the wider Bedfordshire area. We offer a complete service – from concept to component – tailored to suit your design, budget, and supply chain requirements.

From engineered brackets and housings to packaging parts and aesthetic enclosures, our ISO 9001:2015-certified production process ensures every part is made with precision and repeatability.

We serve both established brands and emerging innovators across sectors including aerospace, electronics, medical, and consumer products.

End-to-End Manufacturing for Luton’s Industries

Luton’s industrial base – particularly its aerospace legacy, automotive logistics, and growing manufacturing SMEs – demands a flexible, high-performance approach to plastic part production.

At Stephens Plastic, we offer a comprehensive suite of services that keeps your entire project under one roof:

- Design & Engineering Support: We review CAD designs for mouldability, tolerance management, and optimal part geometry.

- Toolmaking: Our in-house toolroom produces aluminium and steel moulds for short and long production runs.

- Prototype Sampling: We offer rapid prototyping via soft tooling or trial runs, ensuring functional testing before full-scale production.

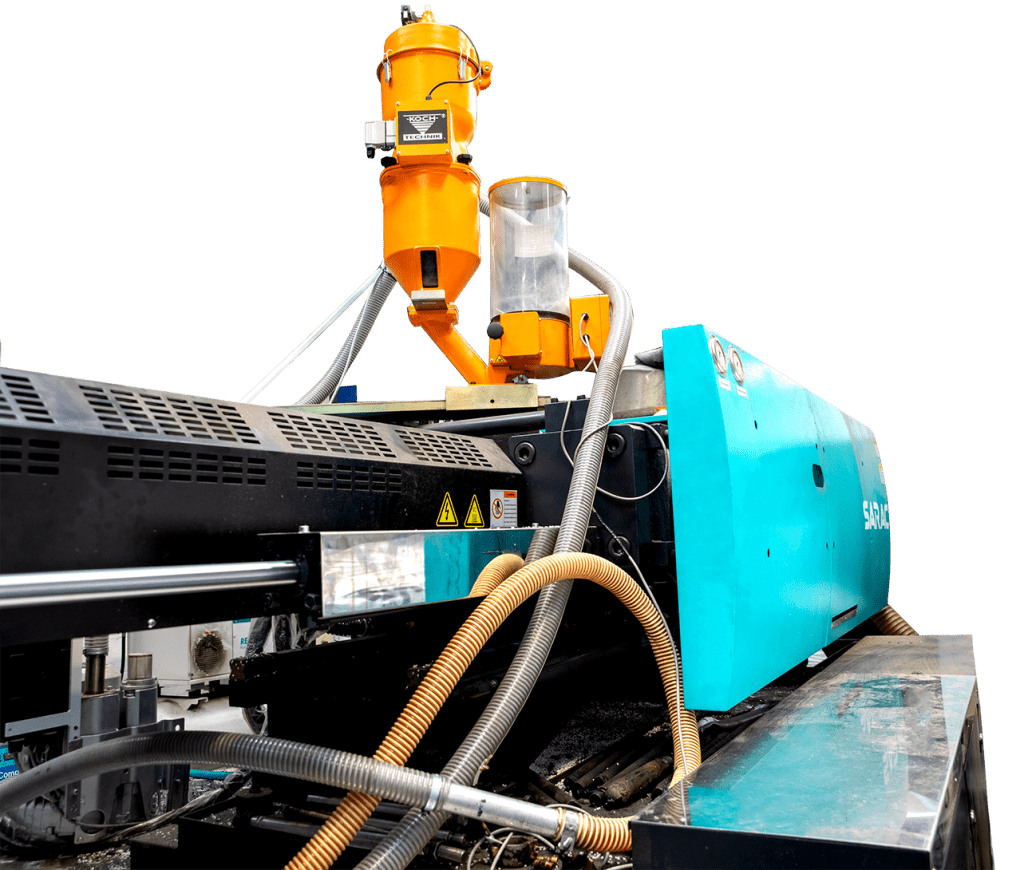

- Plastic Injection Moulding: High-quality, precision-moulded components with consistent finish and dimensional accuracy.

- Post-Mould Operations: Assembly, trimming, ultrasonic welding, and specialist finishing to meet your final specifications.

- Flexible Logistics: We handle batch orders, call-off schedules, and nationwide delivery – with responsive lead times to match your deadlines.

What Sets Us Apart?

Our team brings decades of real-world moulding and tooling experience to your project. We don’t just manufacture - we advise, collaborate, and deliver.

From ABS, PP, and polycarbonate to engineering polymers like PBT, PA, and elastomers - we help you choose the right plastic for durability, compliance, and performance.

Whether you need 100 parts or 100,000, we'll scale production around your needs without rigid minimum order quantities.

We're proud to serve Luton from our UK-based facility - providing the benefits of local insight with national coverage.

No hidden fees. No last-minute surprises. Just clear, competitive quotes built around your brief.

Applications of Plastic Injection Moulding in Luton

We support a broad mix of businesses across Luton. Typical projects include:

- Aerospace & Transport: Lightweight, flame-retardant plastic components.

- Medical & Health: Diagnostic trays, device casings, and single-use plastics.

- Logistics & Packaging: Clip fittings, crates, enclosure housings.

- Consumer & Retail: Branded products, custom enclosures, POS components.

Injection moulding is ideal for producing functional, repeatable parts at volume – helping Luton businesses improve margins, speed to market, and product quality.

How Does Plastic Injection Moulding Work?

The injection moulding process uses a custom-built mould cavity to form heated plastic into precise shapes under high pressure. Once cooled, the plastic component is ejected and the cycle repeats. This fast, closed-loop system allows thousands of consistent, high-quality parts to be produced with minimal waste.

For manufacturers in Luton looking for both scalability and precision, injection moulding provides unbeatable cost-efficiency and design control.

FAQs

Yes, we offer prototype tooling and low-volume sampling so you can evaluate performance and fit before proceeding to production.

We work with standard and specialist plastics including ABS, PP, PA, PBT, TPE, and flame - retardant or medical-grade materials.

Tooling typically takes 3 - 6 weeks. Once approved, parts can be produced and shipped in as little as 2 - 10 working days depending on quantity and complexity.

Yes - we offer repeat manufacturing, call-off ordering, and flexible scheduling to support your stock and production needs.

Absolutely. We can assess and run customer-supplied tools, provided they are compatible with our equipment and meet safety standards.

Work With a Proven Plastic Injection Moulding Company

Stephens Plastic Mouldings helps businesses in Luton transform designs into market-ready products – efficiently, accurately, and on time.

Whether you need a reliable manufacturing partner for long-term growth or help bringing a product to market, we’re here to deliver.

Serving Luton and Bedfordshire | UK Manufacturing Excellence | ISO 9001 Certified.

Request a Quote OR

Speak to our Engineers today OR Visit Website

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.