Plastic Injection Moulding North West

When you need high-quality, reliable plastic injection moulding in North West England, Stephens Plastic Mouldings is here to deliver.

We understand that you seek certainty in quality and deadlines, as well as innovation to keep your products competitive. As a leading UK manufacturer, we strive to fulfil these needs while forging a genuine partnership built on trust and shared success.Our emotionally resonant approach means we don’t just make plastic parts – we help you achieve your vision with confidence and peace of mind. With over 20 years of industry experience at the forefront of UK plastics manufacturing, our team offers unmatched expertise and flexibility.

No project is too big or too small – whether you require a handful of prototype parts or a full production run of millions, we have the capability and commitment to make it happen. We pride ourselves on quality at every step (we have been ISO 9001 certified since 2011) and competitive pricing to ensure you get outstanding value.

Stephens Plastic Mouldings is a UK-based company with a nationwide reach, providing strong local support for businesses across the North West region. We even stepped up to support the NHS with critical PPE components when it mattered most, demonstrating our dependability and contribution to the community.

Should you require regional case studies or client references, our team would be happy to discuss these with you directly. Due to the nature of our work, many projects are governed by NDAs; however, we can share appropriate experience and outcomes across most sectors and locations on a confidential basis.

Why Choose Stephens Plastic Mouldings?

We offer cost-effective injection moulding solutions without compromising on quality. Our efficient processes and lean production practices keep your unit costs low while ensuring superior results.

As a British injection moulding company, we serve clients across the UK with ease. North West businesses enjoy the responsiveness of local support backed by the resources of a national supplier - the best of both worlds.

To give you added certainty, we provide free trial tooling options for new projects. This means you can validate and refine your part design with prototype tools at no initial cost, ensuring the final production mould is perfect.

Quality is at the heart of everything we do. Our ISO 9001-certified quality management system underpins every stage of production, from material sourcing to final inspection, so you can trust every batch of parts will meet your specifications.

Plastic Injection Moulding North West

Plastic injection moulding is a specialised manufacturing process that demands skill, precision, and experience. To get the results your business expects, you need a partner at the forefront of the industry to handle your project from start to finish. If you are looking for plastic injection moulding in the North West, you can count on Stephens Plastic Mouldings to deliver exactly what you need.

We have successfully delivered injection moulded products for companies in a wide range of sectors nationwide (including many in North West England), and our knowledge and expertise set us apart from the competition. Our dedicated team of injection moulding specialists is on hand to cater to your every requirement, customising our services to fit your project.

We can assist at any stage of development:

From initial product design and CAD modelling to precision machining of new mould tools. If you already have tooling, we will efficiently manufacture your plastic components and assemblies with equal care and attention. Or, if you prefer a full-service partner to oversee the entire venture from concept through to the final packaged product, we have the project management expertise to deliver a seamless, stress-free experience. We pride ourselves on building strong relationships – when you work with Stephens Plastic Mouldings, you’re not just a customer, you’re a partner in the process.

What is injection moulding in the North West?

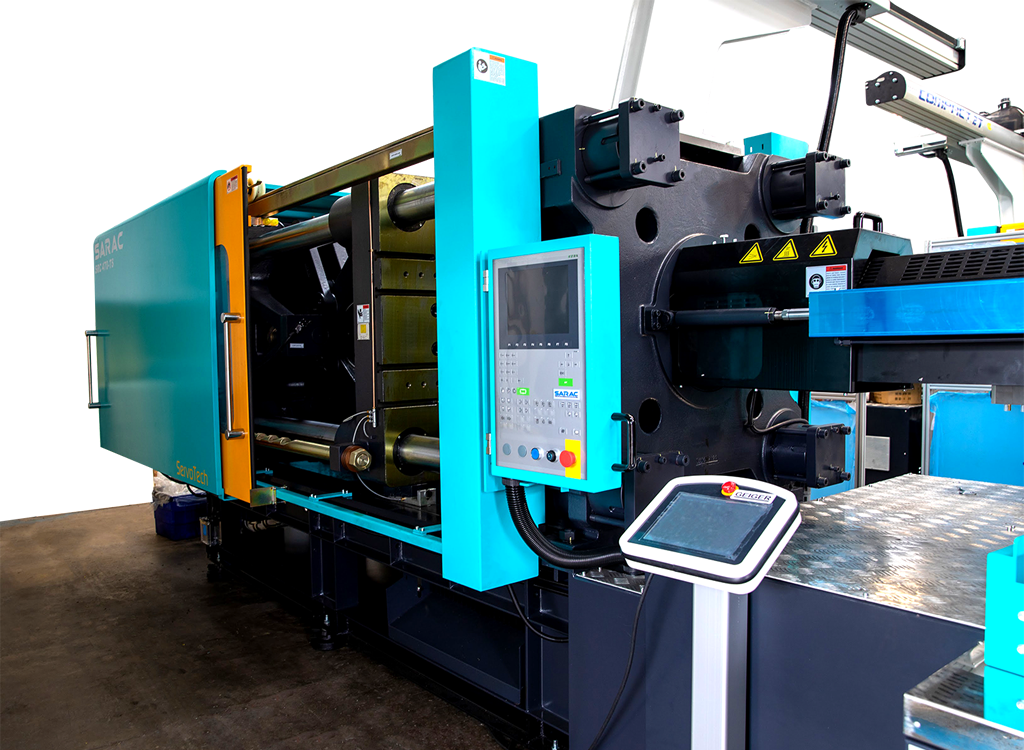

Plastic injection moulding is one of the most common and versatile methods for producing plastic parts. It’s used to create many of the everyday items we rely on – from bottle caps, packaging containers and children’s toys, to automotive components and medical device housings. The process uses a cyclical heating and cooling technique that produces parts with fine detail and a consistent finish.

This high level of precision and repeatability makes injection moulding ideal for both high-volume production and intricate, complex designs. In the injection moulding process, a custom mould “tool” is first engineered for your part. The mould is typically CNC-machined from metal (often steel or aluminium) to form the exact negative shape of the component. Thermoplastic material (such as ABS, polypropylene, nylon, etc.) is then heated until molten in an injection machine and forced under pressure into the mould cavity.

Once the plastic fills the cavity, it is cooled until solid, capturing every detail of the design. The mould then opens and the newly formed part is ejected, and the cycle can repeat. This efficient process can produce hundreds or even thousands of identical parts per hour with minimal variance, ensuring consistent quality across all units. For businesses in the North West and beyond, injection moulding offers a reliable way to scale production while maintaining tight quality control on every piece.

FAQs

We serve a wide range of industries including automotive, medical, electronics, consumer goods, construction, and engineering. Our diverse experience means we can tailor our injection moulding services to the specific needs and regulations of your sector.

Absolutely. No volume is too big or too small for us - we are equipped to produce everything from small prototype batches to large-scale mass production runs. Our facility and team adapt to your project’s size, ensuring cost-efficiency and fast turnaround at any volume.

Yes, we provide full design for manufacture (DFM) and prototyping support. Our engineers can assist with CAD design, material selection, and 3D-printed or machined prototypes. This helps verify your design and make any needed adjustments before investing in full production tooling.

Quality is our top priority. We maintain an ISO 9001-certified quality management system, which includes in-process inspections and rigorous post-production testing. Every part undergoes quality checks for critical dimensions and appearance, ensuring consistent results across the entire batch.

We work with a wide range of thermoplastic polymers to suit different applications. Common materials include ABS, polycarbonate, polypropylene, polyethylene, nylon, acrylic, and many more. We’ll recommend the best material for your project based on the required strength, flexibility, heat resistance, and finish.

Lead times can vary depending on the complexity of the part and the tooling required. Generally, once a mould tool is made, initial production samples can be ready in a few weeks. Full production runs are often completed within 2-6 weeks after tooling, but we always provide a realistic timeline upfront and strive to meet any urgent deadlines.

The main cost factors are the part’s design complexity, the type of material used, the number of cavities in the mould (which affects how many parts are made per cycle), and the size of the production run. While there is an upfront investment in tooling, injection moulding becomes very cost-effective at higher volumes. We are transparent with pricing and will help you understand how to optimize your design or order quantity to get the best value.

Yes - our advanced tooling and moulding processes can achieve intricate details and tight tolerances. We have experience producing complex geometries, thin-walled parts, and components that require high precision. Our mould makers and process engineers ensure that even challenging designs are manufactured accurately and reliably.

We are committed to sustainability in our operations. We can work with recycled plastics or bioplastics where suitable, and our processes are designed to minimize waste (for example, by recycling surplus plastic sprues and runners). We also continually invest in energy-efficient machinery and smart process controls to reduce our environmental footprint.

Yes. While our production facility is based in the West Midlands, we serve customers all across the UK. We have strong regional support for clients in North West England - you'll get timely communication and delivery to your location. Our national logistics network ensures that no matter where you are in the UK, you receive the same prompt service and attention as our local customers.

Ready to Discuss Your Project?

We’d love to hear about your next plastic moulding project. Get in touch with us for a free consultation or a no-obligation quote.

Contact Stephens Plastic Mouldings

Our friendly team is ready to answer any questions and help you take the next step toward bringing your product to life.

Call 0121 544 5808 OR Email sales@stephensplasticmouldings.co.uk.

Let Stephens Plastic Mouldings be the partner you trust for plastic injection moulding in the North West – We’re here to support your success every step of the way.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.