Injection Moulding Costs & Charges

Injection Moulding Costs & Charges

Using injection to produce high quality plastic injection mouldings for industrial and consumer use, we start from the initial design and prototype stage and manufacture mouldings according to different requirements and meeting different usage circumstances. The dedication of Stephens Plastic Mouldings as a company results in precision and quality. Our plastic injection mouldings cover the entire range of articles for industry purposes. Full project management is one of the areas where we offer expertise and experience. We also work in the R&D area, with a keen interest on innovations. We pay attention both to your needs for tooling by moulding new or already designed tools, and to your needs for plastic injection mouldings for vast consumer use.

Organising our design and manufacturing activities, we work as a team to achieve the best quality and results. We have been on the market for over 20 years, and we have established our name as a symbol of quality in the production of plastic injection mouldings.

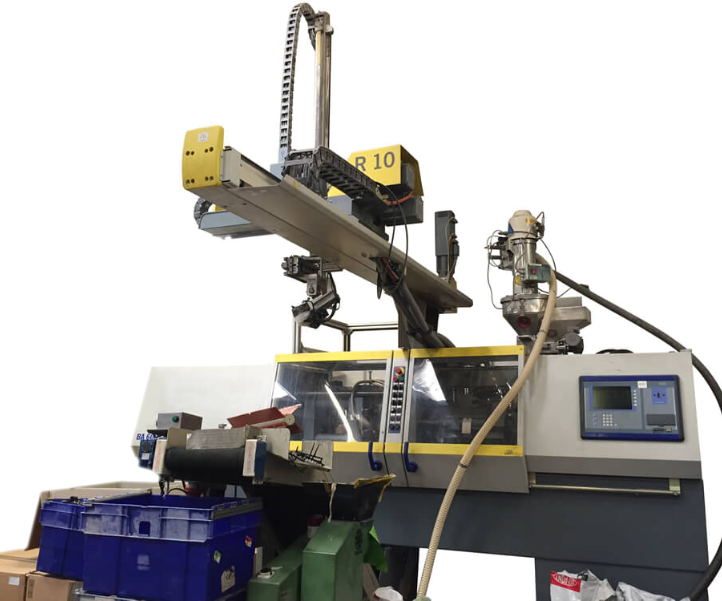

Injection Moulding Process

The essence of injection moulding is that first the material is heated and then it is left to cool and harden in moulds of the desired form. The materials used are thermoplastics or thermosetting plastics. They are heated in barrels until a uniform mixture is formed. Then the mixture is forced into moulds where the cooling and hardening take place. The hardened plastic material takes the necessary mould shape. The exact shape is obtained by producing moulds from metal, steel or aluminium, and then precision machining the ready moulds. Moulds can have different sizes, and both small items and large ones such as entire car body panels can be produced as plastic injection mouldings. Examples of well known plastic injection mouldings are also packaging, dashboards, bottle caps, containers, mechanical parts.

We’d Love to Hear From You, Get In Touch With Us!

Please contact us if you would like to receive a quotation and/or to find our more about how we can provide the service you are looking for.